Opcenter Intra Plant Logistics

Opcenter Intra Plant Logistics streamlines material flow within plants, enhancing efficiency and reducing operational costs by optimizing internal supply chains.

Manufacturers use it to increase efficiency in logistics flows, decrease handling costs, and improve responsiveness to production schedule changes, helping maintain competitive production processes.

What is Opcenter IPL?

Intra Plant Logistics is a system that streamlines manufacturing by managing the real-time flow of materials from storage to production lines. It optimizes the placement and movement of materials to ensure they are precisely where they are needed when they are needed. This minimizes delays and maximizes production efficiency.

Enhanced Manufacturing With Opcenter Intra Plant Logistics

The adoption of Intra Plant Logistics enables manufacturers to quickly adapt to changes in production demands and schedules while maintaining necessary inventory levels without surplus.

This fosters a more agile and responsive manufacturing environment, reducing the physical and time-related constraints typically associated with material handling and storage.

The outcome is a more efficient production process with reduced downtime due to material shortages and enhanced operational throughput.

Key Advantages of Opcenter IPL

Increased Efficiency

Reduces the time materials spend in transit or storage, directly boosting production speed.

Reduced Costs

Lowers expenses related to material handling and storage by optimizing resource allocation.

Enhanced Responsiveness

Improves the ability to adapt to production changes with real-time material management.

Decreased Downtime

Minimizes production halts due to material shortages by ensuring timely supply.

Improved Inventory Management

Reduces excess stock and associated costs through better inventory accuracy and forecasting.

Greater Scalability

Facilitates easier scaling of operations to meet increased demand without the need for proportionate increases in inventory.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

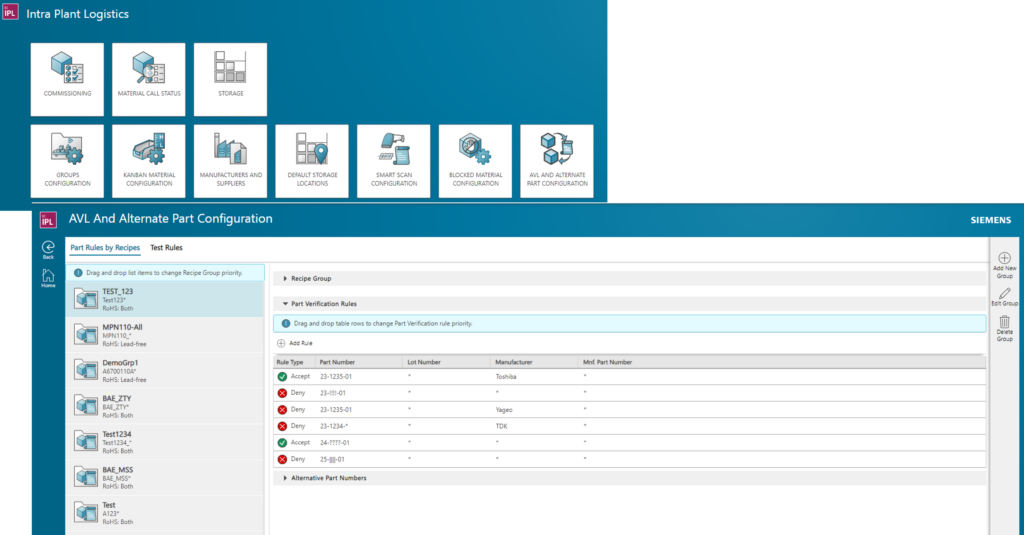

Implementing Intra Plant Logistics

Integrating Opcenter Intra Plant Logistics involves connecting it with ERP and MES systems through APIs, starting with a thorough platform analysis to enhance control and improve visibility across manufacturing operations.

What are the benefits of implementation?

Implementation boosts operational efficiency by ensuring real-time data accuracy and streamlining operations. It also enhances responsiveness to supply and demand changes, automates processes, and allows for scalable and flexible business adaptations.

Signs you need Opcenter Intra Plant Logistics

Frequent Production Delays

If production is consistently delayed due to the unavailability of necessary materials at the right time and place, implementing Intra Plant Logistics can help streamline material flows and reduce these delays.

High Inventory Costs

When there is excessive capital tied up in inventory, suggesting inefficiencies in inventory management, Intra Plant Logistics can optimize the use and storage of materials, reducing overall inventory costs.

Complex Material Handling

In facilities where material handling is complex due to the diversity of products and components, Intra Plant Logistics can simplify and automate these processes, making them more efficient.

Wasted Labor Hours

If workers spend a significant amount of time retrieving or waiting for materials, Intra Plant Logistics can minimize these non-productive periods by improving the logistics workflow.

Inconsistent Production Output

Variability in production output that stems from logistical inefficiencies can be addressed by Intra Plant Logistics, which ensures a steady and predictable flow of materials to production lines.

Low Space Utilization

If physical space is poorly utilized due to inefficient storage of materials and components, Intra Plant Logistics can help optimize space usage, freeing up room for more productive uses.

Partner With Us To Reduce Your Technical Debt

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

Why Manufacturers Struggle to Use Data — and How Data Integration Fixes It

How is a Gantt Chart Used in Manufacturing Process?

.png)

Top Advantages of Laboratory Automation Systems

Frequently Asked Questions

Have Question? We are here to help

How does Opcenter Intra Plant Logistics integrate with existing systems?

It integrates seamlessly with existing ERP, MES, WMS, and SCM systems through APIs and standardized data exchange formats, enabling real-time data flow and enhancing operational visibility.

What are the primary benefits of using Opcenter Intra Plant Logistics?

The key benefits include increased operational efficiency, reduced material handling costs, improved production responsiveness, enhanced inventory management, and better utilization of space.

Can Opcenter Intra Plant Logistics handle complex manufacturing environments?

Yes, it is designed to manage and simplify complex material flows in diverse manufacturing environments, supporting multiple production methods and product variants.

How does Opcenter Intra Plant Logistics improve inventory management?

It optimizes inventory levels by providing real-time visibility and tracking of material usage, reducing excess stock and minimizing storage costs.

What is required to implement Opcenter Intra Plant Logistics in a facility?

Implementation typically requires an initial assessment of existing workflows and IT infrastructure, followed by system integration and staff training to ensure smooth operation.

How does Opcenter Intra Plant Logistics impact production scheduling?

It enhances production scheduling by providing accurate, real-time information on material availability, which helps in making informed decisions to optimize production runs and reduce downtime.

Is training available for staff on how to use Opcenter Intra Plant Logistics?

Yes, comprehensive training is provided for staff to ensure they are proficient in using the system and can leverage its full capabilities to enhance manufacturing operations.

Can Opcenter Intra Plant Logistics support sustainable manufacturing practices?

Absolutely, by optimizing material flow and reducing waste, it supports more sustainable manufacturing practices and can help facilities reduce their environmental impact.

Siemens Opcenter IPL

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter Intra Plant Logistics.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)