Insights Hub Solutions

By connecting machines, systems, and processes, Insights Hub empowers manufacturers to optimize performance, reduce downtime, and make data-driven decisions that enhance productivity and product quality.

What is Insights Hub?

Insights Hub is Siemens’ cloud-based Industrial IoT (IIoT) platform, part of the Industrial Operations X portfolio. It enables manufacturers to connect machines, sensors, and systems to the cloud, collect and analyze data in real time, and generate actionable insights for smarter decision-making.

Why Partner with Snic Solutions?

By partnering with Snic Solutions, manufacturers gain a trusted partner with a deep understanding of manufacturing operations, helping them leverage the full potential of Insights Hub to drive smart manufacturing and Industry 4.0 transformation.

Platform Overview

Cloud-based IIoT platform that transforms industrial data into actionable insights for smarter decisions and improved operations.

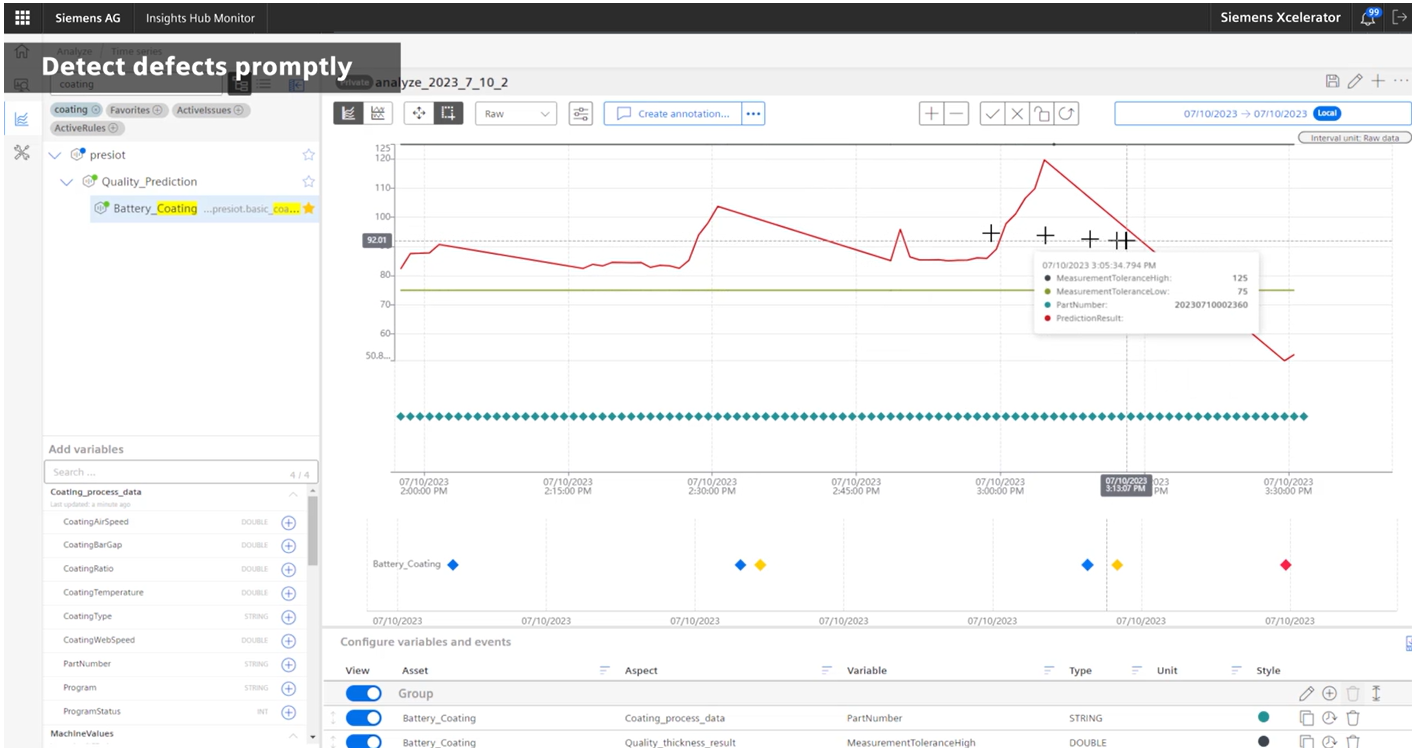

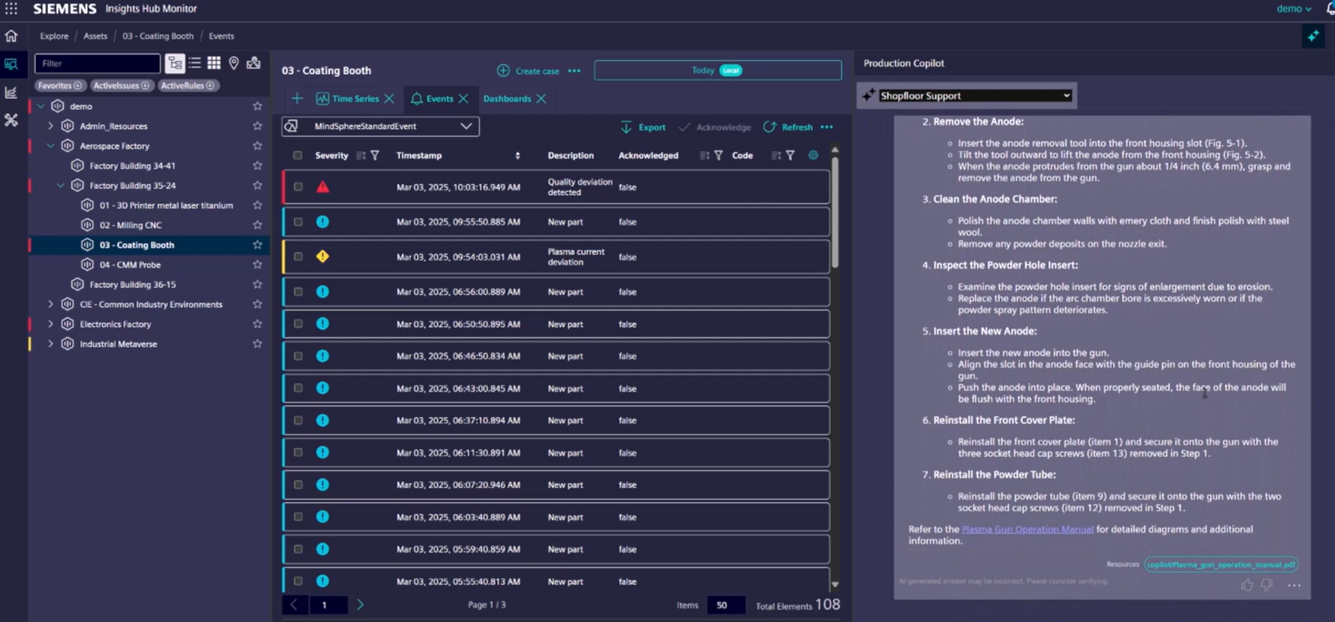

Insights Hub Monitor

Monitor asset data in real time to detect anomalies, visualize trends, and ensure operational transparency.

Insights Hub OEE

Track and analyze production efficiency with real-time KPIs to identify losses and optimize performance.

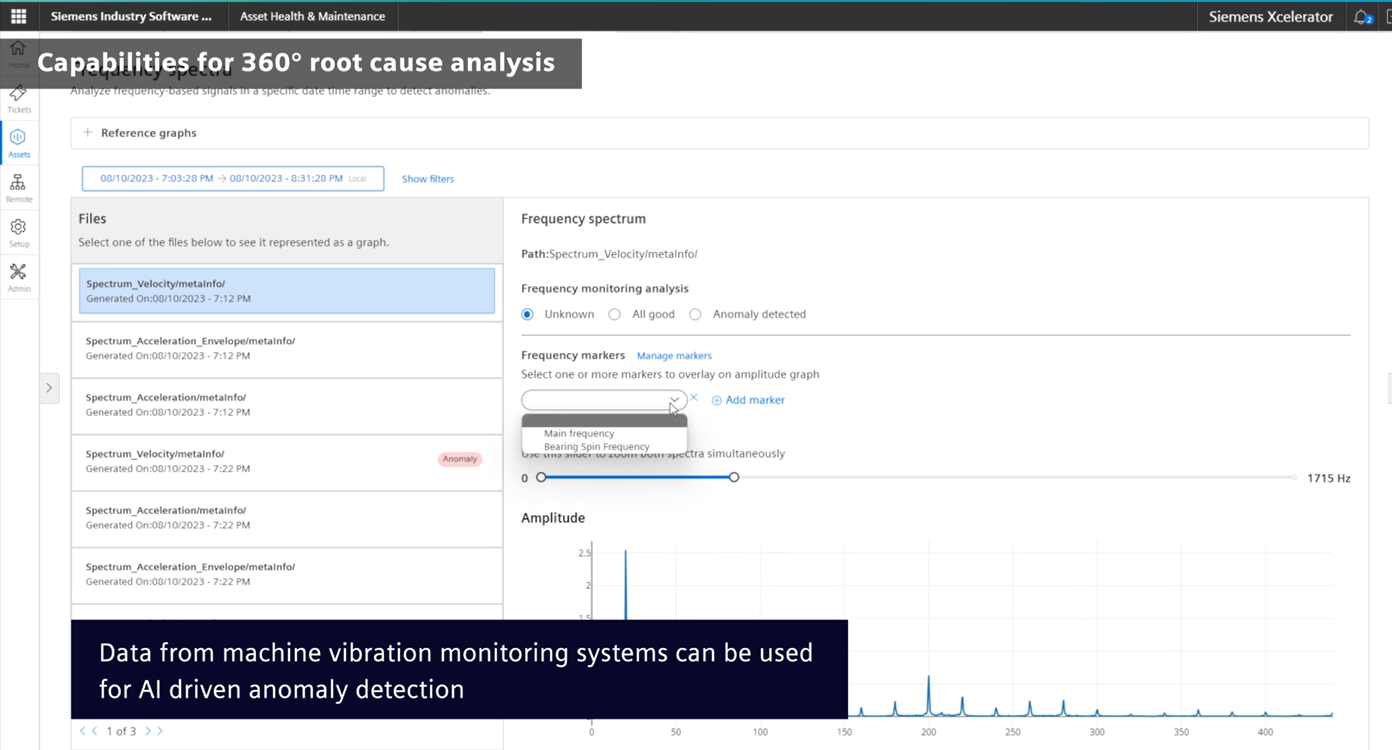

Insights Hub Asset Health & Maintenance

Predict and prevent equipment failures using condition monitoring and data-driven maintenance insights.

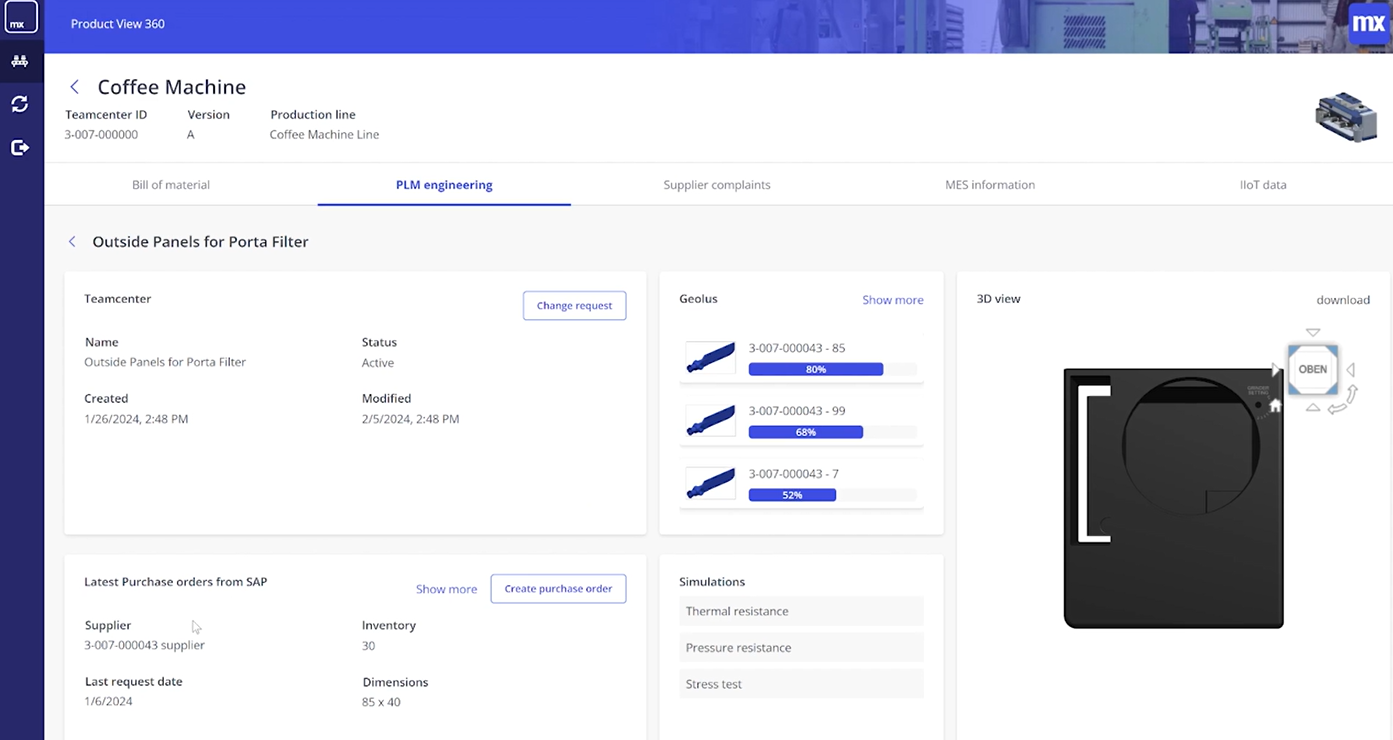

Insights Hub Developer Tools (Mendix)

Create custom apps and dashboards quickly with Mendix low-code tools tailored to your operations.

Insights Hub Production Copilot

AI assistant that delivers contextual insights from machine and process data via natural language queries.

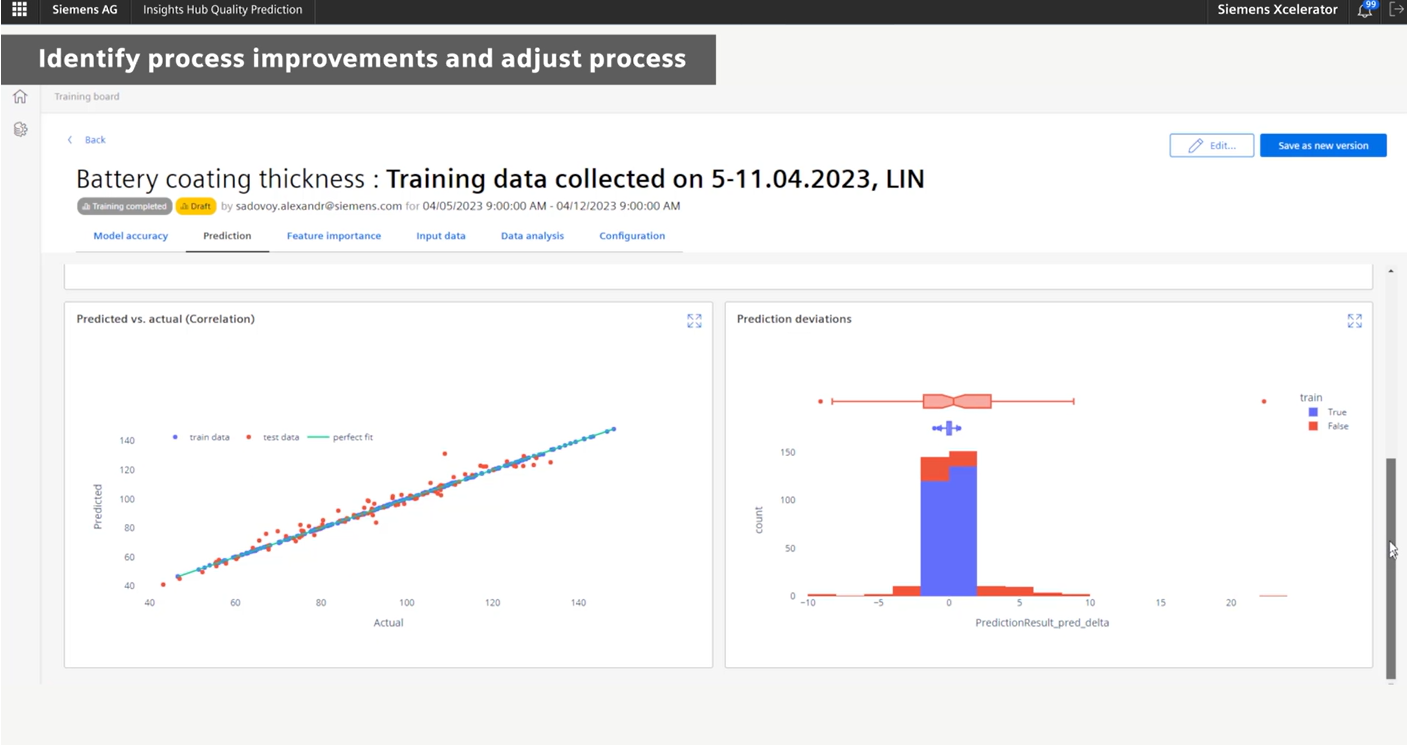

Insights Hub Quality Prediction

Use AI to detect quality risks early, identify root causes, and minimize defects and rework.

Insights Hub Capabilities

Predictive Learning

Make every decision smarter with machine learning. Automatically learn from historical data to improve accuracy in forecasting and decision-making.

Security & Compliance

Operate with confidence in a secure environment. Benefit from enterprise-grade security, data encryption, access controls, and full compliance with global standards.

Data Exploration

Insights Hub enables users to connect assets and visualize real-time data through customizable dashboards and time-series analysis. This helps identify trends and anomalies to better understand operational performance.

Outcomes

Boost Operational Efficiency

Optimize processes and increase productivity with real-time monitoring and data-driven improvements.

Reduce Unplanned Downtime

Predict equipment issues early to prevent failures and keep production running smoothly.

Improve Product Quality

Use AI to detect and prevent quality problems before they affect output or cause rework.

Lower Operational Costs

Minimize waste, reduce energy usage, and extend asset life through smart data insights.

Enable Faster Decisions

Access live data and analytics to support smarter decisions and continuous operational optimization.

See Insights Hub Live in Action

Schedule a live demo to discover how top manufacturers unlock data-driven control with Insights Hub.

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

Why Manufacturers Struggle to Use Data — and How Data Integration Fixes It

Alex is an operations leader at a manufacturing plant. He’s aware that his IT team…

How is a Gantt Chart Used in Manufacturing Process?

In manufacturing, Gantt charts are used to simplify production by visualising task…

.png)

Top Advantages of Laboratory Automation Systems

Are you curious about how laboratory automation can benefit your lab? Laboratory a…

Frequently Asked Questions

Have Question? We are here to help

What is an Insights Hub?

What is the new name for Siemens MindSphere?

Which of the following is a key feature of Siemens Insights Hub?

Key features include:

-

Real-time monitoring and visualization of assets and operations

-

Predictive maintenance and asset health analytics

-

AI-driven quality prediction

-

Low-code app development via Mendix

-

Integration with digital twins and Siemens Xcelerator ecosystem.

What are the benefits of Siemens MindSphere (now Insights Hub)?

Benefits include:

-

Improved asset utilization and operational efficiency

-

Reduced downtime through predictive maintenance

-

Enhanced product quality and faster innovation

-

Scalability and flexibility across deployment models (public cloud, VPC)

-

Accelerated digitalization with built-in analytics and low-code customization.

Partner With Us To Reduce Your Technical Debt

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Insights Hub.

%20(1).png?width=500&height=500&name=Nikhil%20Digital%20Transformation%20Solutions%20(2)%20(1).png)