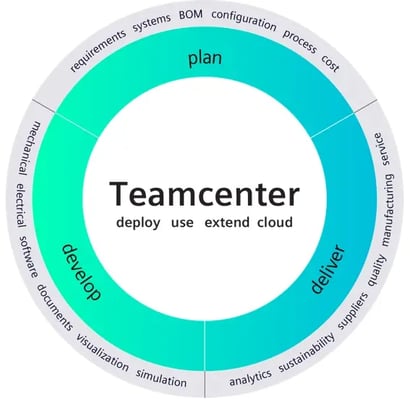

Teamcenter Solutions

Teamcenter accelerates smart manufacturing by integrating the digital thread across design, manufacturing, and service, ensuring real-time data flow, traceability, and early validation through model-based systems engineering.

What is Teamcenter?

Teamcenter is a comprehensive Product Lifecycle Management (PLM) platform that enables manufacturers to streamline operations, enhance collaboration, and drive innovation across the entire product lifecycle.

Teamcenter Capabilities

Product Data Management

Centralizes all product-related information (CAD files, documents, BOMs) for easy access and collaboration.

Change Management

Tracks and manages product changes with built-in workflows and approvals.

Bill of Materials (BOM) Management

Maintains accurate, multi-domain BOMs to align engineering, manufacturing, and service teams.

Manufacturing Process Planning

Aligns engineering with production through detailed process plans and work instructions.

Product Cost Management

Estimates and analyzes product and manufacturing costs, including transport and carbon footprint.

Supplier and Service Lifecycle Management

Improves collaboration with suppliers and supports service operations with accurate product data.

Why partner with Snic Solutions?

By partnering with Snic Solutions, manufacturers gain a trusted partner with a deep understanding of manufacturing operations, helping them leverage the full potential of Teamcenter to drive smart manufacturing and Industry 4.0 transformation.

Teamcenter Products

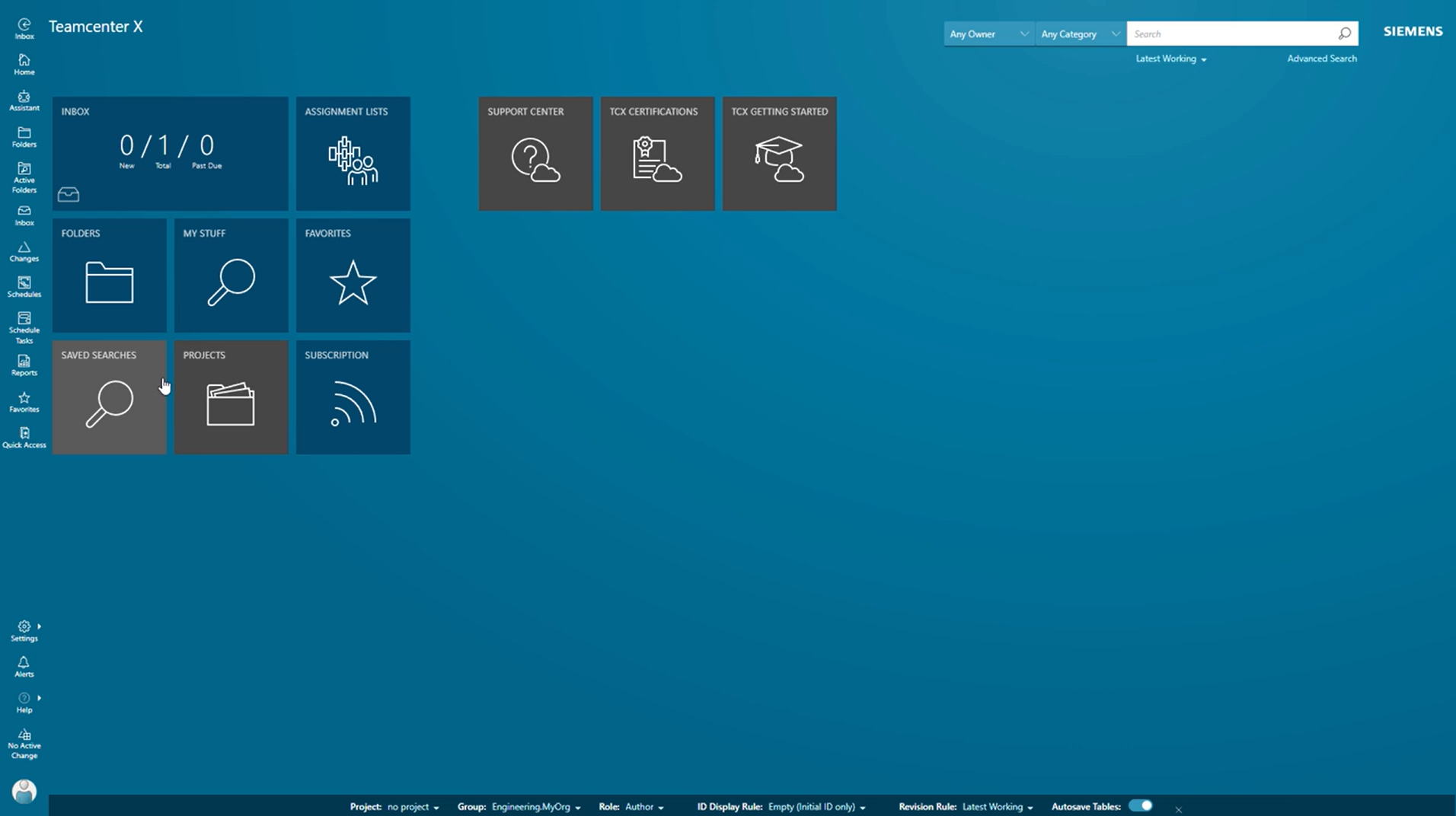

Teamcenter X

The cloud-based, SaaS version of Teamcenter offering fast deployment, scalability, and reduced IT overhead.

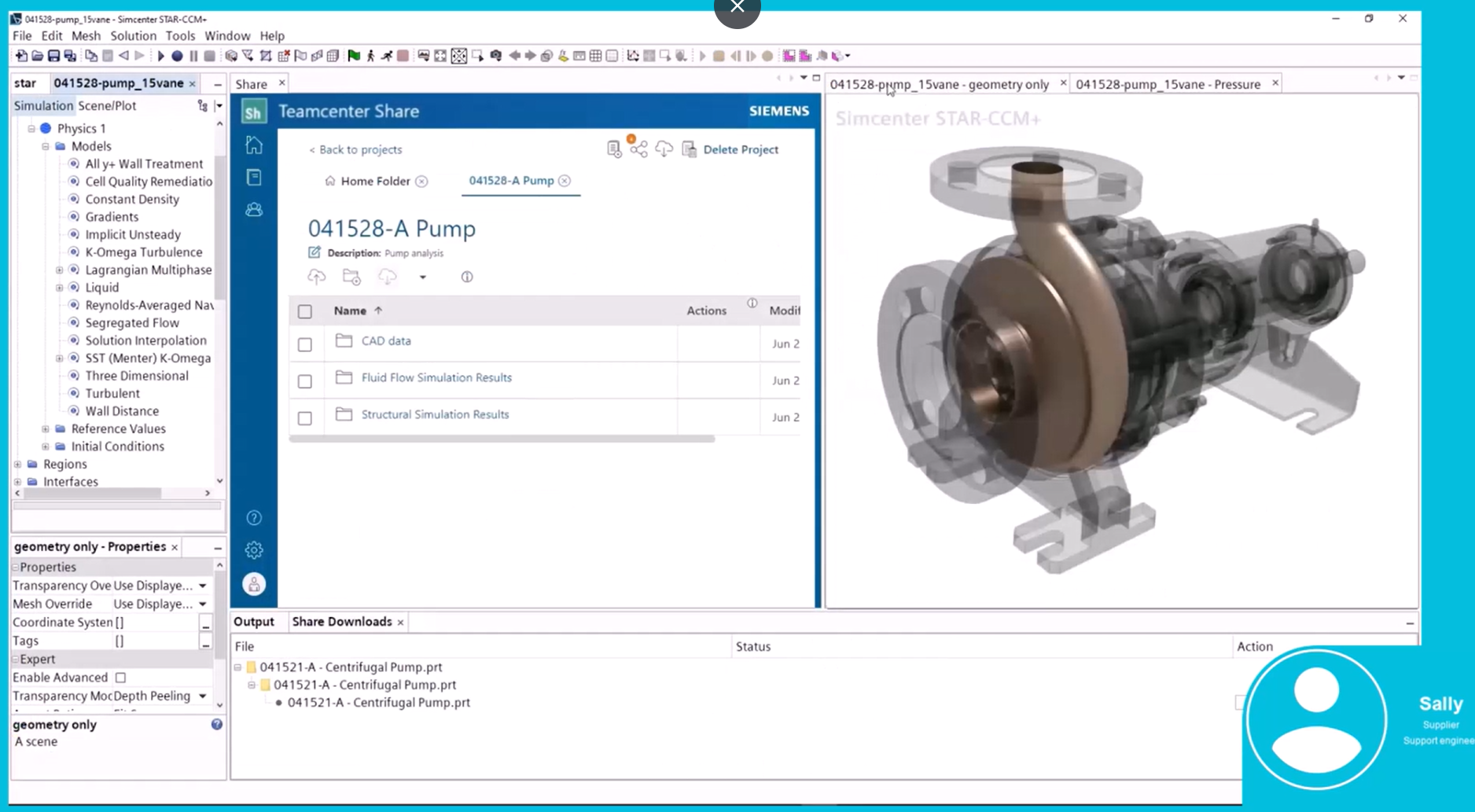

Teamcenter Share

Manages simulation data and processes, integrating with analysis tools to ensure product performance.

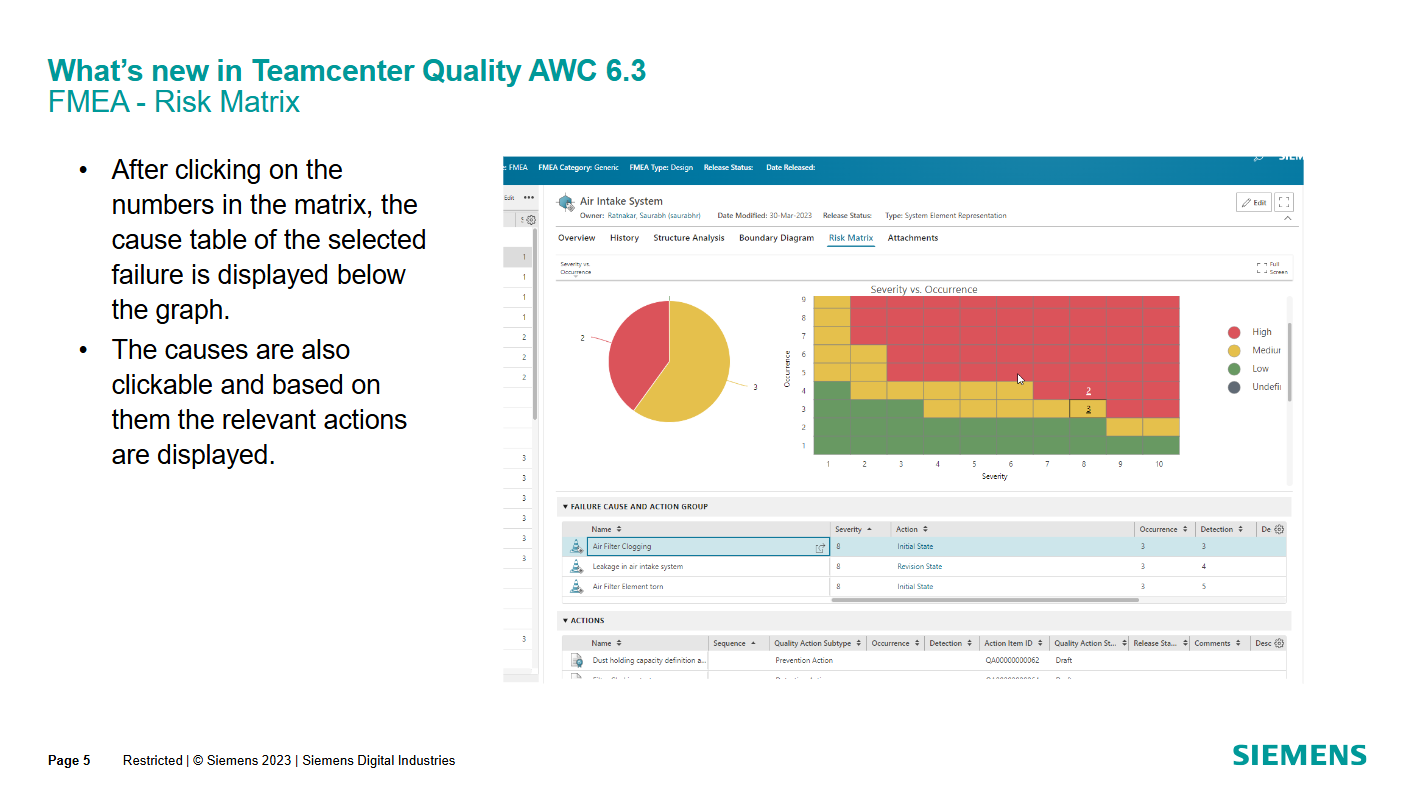

Teamcenter Quality

Predict and prevent equipment failures using condition monitoring and data-driven maintenance insights.

Outcomes

Accelerate Time-to-Market

Connect teams and processes to launch products faster.

Unify Product Data

Break down silos with a single source of truth.

Streamline Change Management

Respond quickly and confidently to design changes.

Reduce Costs

Cut waste, rework, and inefficiencies across the lifecycle.

Ensure Quality and Compliance

Build better products with embedded standards and traceability.

See Teamcenter Live in Action

Schedule a live demo to discover how top manufacturers unlock data-driven control with Teamcenter.

Digital Transformation With Teamcenter

Northrop Grumman Corporation leverages product lifecycle management (PLM) to connect data, empower people, and power digital transformation.

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

Why Manufacturers Struggle to Use Data — and How Data Integration Fixes It

Alex is an operations leader at a manufacturing plant. He’s aware that his IT team…

How is a Gantt Chart Used in Manufacturing Process?

In manufacturing, Gantt charts are used to simplify production by visualising task…

.png)

Top Advantages of Laboratory Automation Systems

Are you curious about how laboratory automation can benefit your lab? Laboratory a…

Frequently Asked Questions

Have Question? We are here to help

How do I get started with Teamcenter?

What kind of support and training is available?

Can Teamcenter integrate with other tools?

Yes. Teamcenter integrates with major CAD tools, ERP systems, simulation platforms, and Microsoft Office, enabling a connected digital thread.

What’s the difference between Teamcenter and Teamcenter X?

Teamcenter X is the SaaS (cloud-native) version of Teamcenter, offering faster deployment, reduced IT overhead, and automatic updates—all managed by Siemens.

Elevate Your Manufacturing

See how Teamcenter connects your systems, breaks down data silos, and boosts plant performance—live and in real-time. Schedule a demo to explore the platform’s capabilities firsthand.