Non-Conformance Management Software

In smart manufacturing, managing nonconformances quickly and accurately is essential. Nonconformance Management Software streamlines this process by automating detection, tracking, and resolution.

It standardizes investigations and maintains clear audit trails. This supports real-time decisions, stronger compliance, and continuous improvement across connected systems.

Non-Conformance Management Challenges

Managing nonconformances manually leads to delays, inconsistent documentation, and limited visibility across departments. Without digital tools, teams often struggle with disorganized investigations, poor accountability, and missed compliance targets—resulting in costly errors and repeated quality issues.

What Does Non-Conformance Management Software Do?

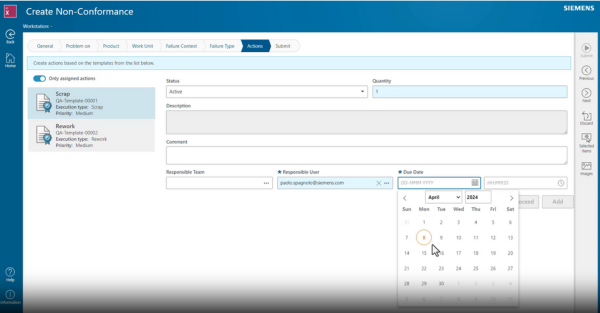

Nonconformance software simplifies and digitizes how deviations are reported, investigated, resolved, and documented. It ensures each issue is tracked through a consistent, auditable process, supporting faster resolutions and stronger compliance. This software fits seamlessly into smart manufacturing by enabling connected quality oversight across systems and teams.

Key Features

Centralized Issue Logging

Log, manage, and monitor all quality issues in one system. Improve visibility, traceability, and accountability across teams and product lines.

Automated Workflows

Trigger alerts, assign tasks, and route approvals automatically. Ensure timely resolution and eliminate bottlenecks in your quality management process.

Root Cause Analysis Tools

Use guided methods like 5 Whys and Fishbone diagrams to investigate issues, uncover root causes, and implement corrective actions that prevent recurrence.

Benefits

Faster Resolutions

Automated alerts and clear workflows help teams respond quickly and keep issues from stalling.

Improved Product Quality

Structured investigations and corrective actions reduce repeat problems and drive continuous improvement.

Simplified Compliance

Complete, traceable records make it easier to meet regulatory requirements and breeze through audits.

Greater Team Alignment

Cross-functional access ensures everyone—from quality to operations—is working from the same data.

Better Decision-Making

Access to real-time data and trend analysis enables proactive quality control and risk management.

Reduced Operational Costs

Fewer errors and faster resolutions lead to cost savings in materials, labor, and potential recalls.

Siemens Opcenter Quality

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Software Integration

Nonconformance Management Software integrates easily with other enterprise systems to enhance visibility and automation. Whether it’s syncing with MES to catch process deviations or linking to LIMS for test result validation, integration ensures that quality issues are detected early and handled quickly.

What happens when you integrate?

When nonconformance software is integrated with systems like MES or LIMS, quality issues are identified and logged automatically. This real-time connection speeds up resolution and improves overall visibility.

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

Why Manufacturers Struggle to Use Data — and How Data Integration Fixes It

Alex is an operations leader at a manufacturing plant. He’s aware that his IT team…

How is a Gantt Chart Used in Manufacturing Process?

In manufacturing, Gantt charts are used to simplify production by visualising task…

.png)

Top Advantages of Laboratory Automation Systems

Are you curious about how laboratory automation can benefit your lab? Laboratory a…

Frequently Asked Questions

Have Question? We are here to help

What is nonconformance management?

It’s the process of identifying, investigating, correcting, and documenting deviations from defined requirements, whether in products, processes, or systems.

What is non-conforming software?

This refers to software that doesn’t meet its specified requirements, such as failing validation tests or producing incorrect outputs.

What are the tools for non-conformance investigation?

Common tools include 5 Whys, Fishbone (Ishikawa) diagrams, checklists, Pareto analysis, and Failure Mode and Effects Analysis (FMEA).

What is an example of nonconformance?

A batch of packaged products failing inspection due to incorrect labeling or contamination is a typical nonconformance.

What is NCR management?

NCR (Non-Conformance Report) management refers to the tracking and resolution of nonconforming materials, components, or processes.

What does nonconformance mean in business?

In business, nonconformance means any failure to meet agreed-upon requirements or standards, often leading to rework, recalls, or corrective action.

Partner With Us To Reduce Your Technical Debt

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)