Best Medical Device QMS Software in 2025

Are you searching for the right medical device QMS software to ensure compliance and streamline your quality management processes?

In this article, we’ll help you explore the top solutions for regulatory compliance, customization, document review efficiency, and more. Discover which QMS software best fits your medical device company’s needs and ensures your products meet the highest standards.

Overview of Top Medical Device QMS Software

Choosing the right best qms software can significantly impact a medical device company’s ability to meet quality management requirements. Device manufacturers and medical device manufacturers rely on QMS software to comply with regulatory standards, maintain robust quality management systems, and ensure the safety and effectiveness of medical device products.

Here are the top solutions:

-

Best for Integrated Manufacturing Quality: Opcenter Quality

-

Best for Regulatory Compliance: Greenlight Guru

-

Best for Customization: ETQ Reliance

-

Best for Document Review Efficiency: SimplerQMS

-

Best for Cloud-Based Solutions: ComplianceQuest

-

Best for Comprehensive Quality Management: MasterControl

-

Best for Enterprise-Level Quality Management: TrackWise

-

Best for Manufacturing Integration: IQMS

-

Best for Automated Compliance: AssurX

-

Best for Product Lifecycle Management: Arena Solutions

Notified bodies play a key role in certifying medical device products for compliance in various regions, ensuring that manufacturers meet the necessary regulatory requirements.

Opcenter Quality - Best for Integrated Manufacturing Quality

.png?width=1826&height=798&name=Siemens_Opcenter_Portfolio_1-1%20(1).png)

Price: Pricing available upon request

-

Enhances manufacturing quality through integrated compliance and product quality management

-

Detailed analytics and strategic planning tools

Cons:

-

Lack of transparent pricing information

Opcenter Quality is designed to enhance manufacturing quality through integrated compliance management. The software offers detailed analytics and strategic planning tools that improve manufacturing processes and ensure product quality at every stage. Opcenter Quality also supports regular internal audits, helping organizations maintain ongoing compliance, identify nonconformities, and drive continuous improvement. Additionally, the software helps manage customer complaints by collecting feedback and integrating it into the quality management process for corrective actions. Users benefit from its comprehensive tools and integrated approach, though they seek more transparent pricing information.

Despite the unspecified pricing and lack of user reviews, Opcenter Quality’s integrated approach makes it a valuable tool for manufacturers aiming to maintain high standards and competitive advantage.

Rating:

-

Price: 3/5

-

Design: 4/5

-

Functionality: 5/5

-

Customer Support: 3/5

Greenlight Guru QMS Software - Best for Regulatory Compliance

Price: Pricing available upon request

Pros:

-

Simplifies regulatory compliance

-

Specialized tools for document control and training management

-

Facilitates eMDR submissions for adverse event reporting

Cons:

-

Steep learning curve

-

High cost

Greenlight Guru is tailored for medical device companies aiming to ensure compliance with stringent regulatory requirements, particularly those set by the FDA. Greenlight Guru helps organizations meet FDA requirements, including those outlined in 21 CFR Part 820. Its specialized tools streamline compliance documentation and tracking, which is crucial for maintaining high standards of product quality and safety. The software includes modules for document control, training management, and auditing, making it easier to manage and mitigate risks associated with regulatory compliance. It also supports design controls to ensure product realization and regulatory compliance.

Customer feedback highlights its intuitive interface that aids in onboarding new users despite a steep learning curve. Though the software is costly, many users find the investment justified due to the significant efficiency gains and compliance assurance it provides. Greenlight Guru enables companies to align their processes with both regulatory standards and customer requirements.

Rating:

-

Price: 3/5

-

Design: 4/5

-

Functionality: 5/5

-

Customer Support: 4/5

ETQ Reliance QMS Software - Best for Customization

Price: Pricing available upon request

Pros:

-

Highly customizable workflows and modules

-

Extensive reporting tools

-

Strong customer support

Cons:

-

Time-consuming initial configuration

ETQ Reliance stands out for its unparalleled customization capabilities, allowing medical device companies to tailor their quality management processes to specific business needs. Its flexible workflows and modules make it adaptable to various regulatory and operational requirements, providing extensive reporting tools to enhance decision-making and compliance tracking.

While the initial setup can be time-consuming, the software’s adaptability and strong ongoing support make it a valuable asset for organizations looking to create bespoke quality management systems that evolve with their business, including system validation.

Rating:

-

Price: 4/5

-

Design: 4/5

-

Functionality: 5/5

-

Customer Support: 5/5

SimplerQMS - Best for Document Review Efficiency

Price: Pricing available upon request

Pros:

-

Streamlines document review processes

-

Integrates with Microsoft Word for easy collaboration

-

Automates reminders and task assignments

Cons:

-

Limited user reviews

SimplerQMS excels in document review efficiency by offering:

-

Configurable workflows that integrate seamlessly with Microsoft Word

-

Easy document drafting, redlining, and commenting to streamline the review process

-

Accelerated document approval rates

-

Automated reminders and task assignments to keep reviewers engaged and on task

-

Ensured timely feedback and reduced delays

The platform’s user-friendly interface simplifies navigation and document routing, making it an excellent choice for organizations looking to improve their document management efficiency within a single system. However, limited user reviews make it difficult to fully gauge its long-term performance.

Rating:

-

Price: 4/5

-

Design: 5/5

-

Functionality: 4/5

-

Customer Support: 4/5

ComplianceQuest - Best for Cloud-Based Solutions

Price: Pricing available upon request

Pros:

-

Cloud-native architecture for remote access

-

Seamless integration with other cloud services

-

Scalable solution

Cons:

-

Dependency on internet connectivity

-

Data security concerns

ComplianceQuest offers a cloud-based qms solution that integrates various modules to enhance compliance and decision-making efficiency. Its cloud-native architecture supports remote access, facilitating collaboration across dispersed teams and supply chains. Users praise its scalability and seamless integration with other cloud services, which ensures compliance and helps organizations maintain compliance, maintaining compliance and making it a flexible solution for growing organizations.

However, dependency on internet connectivity can be a drawback for users in areas with inconsistent internet access, and data security remains a concern for many users.

Rating:

-

Price: 4/5

-

Design: 4/5

-

Functionality: 5/5

-

Customer Support: 4/5

MasterControl - Best for Comprehensive Quality Management

Price: Pricing available upon request

Pros:

-

All-in-one solution for quality management

-

Strong support for regulatory compliance

-

Automated document routing and approvals

Cons:

-

Higher costs

-

Complex implementation

MasterControl provides a comprehensive quality management solution, encompassing functionalities such as document control, risk management, continuous improvement, and design control. The software automates document routing, reviews, and approvals, ensuring that only the latest versions of documents are accessible. Its strong support for regulatory compliance makes it a reliable option for manufacturers aiming to maintain high standards.

Despite its higher costs and complex implementation, users appreciate the comprehensive features and comprehensive training provided during onboarding, which help maximize the software’s potential.

Rating:

-

Price: 3/5

-

Design: 5/5

-

Functionality: 5/5

-

Customer Support: 4/5

TrackWise - Best for Enterprise-Level Quality Management

Price: Pricing available upon request

Pros:

-

Intuitive user interface

-

Scalable for large enterprises

-

Robust QMS capabilities

Cons:

-

High costs

-

Complex configuration

TrackWise by Sparta Systems is ideal for large enterprises needing robust QMS capabilities that can scale with their business. The intuitive user interface facilitates easy navigation and accessibility across quality processes, making it a valuable tool for managing complex quality management systems. Its scalability is crucial for large organizations that require QMS solutions to grow with their business.

However, the high costs and complex configuration may pose challenges during implementation, requiring significant investment in time and resources.

Rating:

-

Price: 3/5

-

Design: 4/5

-

Functionality: 5/5

-

Customer Support: 4/5

IQMS - Best for Manufacturing Integration

Price: Pricing available upon request

Pros:

-

Integrates quality management with manufacturing processes

-

Real-time tracking and advanced analytics

-

Facilitates better collaboration across departments

Cons:

-

User interface design needs improvement

IQMS excels in integrating quality management directly into manufacturing processes, facilitating better collaboration across departments. The software offers:

-

Real-time tracking

-

Advanced analytics that help manufacturers ensure product quality at every stage of production

-

Manufacturing-focused features providing valuable insights into quality trends and areas for improvement Users value these features for enhancing quality management.

However, some users suggest that the user interface design could be more intuitive to enhance overall usability.

Rating:

-

Price: 4/5

-

Design: 3/5

-

Functionality: 5/5

-

Customer Support: 4/5

AssurX - Best for Automated Compliance

Price: Pricing available upon request

Pros:

-

Fully automated platform for managing quality processes

-

Integrates core quality processes into a centralized repository

-

Robust analytics tools

Cons:

-

Not specified

AssurX features a fully automated platform for managing quality processes, ensuring compliance with various medical regulations without needing third-party tools. The platform offers:

-

Integration of core quality processes like CAPA, audit management, and change control into a single repository, improving efficiency and document management

-

Robust analytics tools that help identify quality issues throughout the product lifecycle

-

Enhanced decision-making and compliance tracking, including corrective and preventive actions

The no-code configurability allows users to create automated workflows tailored to their specific quality management needs, incorporating industry best practices, making it a versatile solution for various industries.

Rating:

-

Price: 4/5

-

Design: 4/5

-

Functionality: 5/5

-

Customer Support: 4/5

Arena Solutions - Best for Product Lifecycle Management

Price: Pricing available upon request

Pros:

-

Robust integration of QMS with PLM

-

Enhances collaboration among product teams and partners

Cons:

-

Not specified

Arena Solutions excels in product lifecycle management (PLM), offering a robust integration of QMS with PLM to enhance collaboration among product teams and partners. This integration ensures that quality management processes are seamlessly aligned with product development, reducing time-to-market and improving overall product quality and product realization.

While detailed user reviews and specific cons are not provided, the strong integration capabilities make Arena Solutions a top choice for organizations focused on comprehensive product lifecycle management.

Rating:

-

Price: 4/5

-

Design: 5/5

-

Functionality: 5/5

-

Customer Support: 4/5

How to Choose the Best Medical Device QMS Software

Choosing the right QMS software for your medical device company involves several critical considerations:

-

Regulatory compliance is paramount.

-

Ensure the software supports compliance with key regulations such as ISO 13485:2016 and FDA Quality System Regulation. The US FDA requires compliance with 21 CFR Part 820 at the time your product is registered with FDA. Establishment registration with the FDA typically occurs when registering your company's first device, which triggers regulatory oversight and inspection by the CDRH.

-

This ensures that your medical devices meet global standards and reduces the risk of non-compliance penalties in medical device quality management, including adherence to QMS requirements and device quality management system. For the European market, notified bodies play a crucial role in certifying medical devices through conformity assessments such as ISO 13485 certification, which is required for CE marking under the EU MDR. A QMS cannot function without solid document control, which is outlined in specific sections of ISO 13485:2016 and the FDA QSR.

Consider the integration capabilities of the quality management system QMS software. It should seamlessly integrate with your existing systems, including ERP, CRM, and other enterprise software, to streamline quality management processes and improve operational efficiency. Additionally, AI capabilities in QMS software can significantly enhance decision-making processes, improving regulatory compliance management and overall product quality. Furthermore, optimizing QMS processes can lead to even greater efficiency in quality management. Effective QMS implementation can further support these goals, helping your business to be successful and evolve over time by incorporating processes that are added, refined, or eliminated.

Summary

Choosing the right QMS software is key for medical device companies to be compliant, streamline quality management processes and improve product quality. From Greenlight Guru’s regulatory compliance to MasterControl’s quality management capabilities, each software reviewed has its own strengths tailored to different company needs. Harmonizing disparate quality management systems into one system may seem daunting but it’s worth it. A quality management system is worthless without a way to measure its performance against planned results.

Ultimately the best QMS software for your company will depend on your specific needs including regulatory compliance requirements, customization preferences and integration capabilities. Making an informed decision will help you maintain high quality, mitigate risks and ensure the safety and efficacy of your medical devices.

Frequently Asked Questions

What is a medical device Quality Management System (QMS)?

A medical device Quality Management System (QMS) is a framework of procedures and processes that ensures the safety and efficacy of medical devices throughout their lifecycle including design, manufacturing and risk management. It’s a structured system of procedures and processes covering all aspects of design, manufacturing, supplier management, risk management, complaint handling, clinical data, storage, distribution and product labeling. This system is required for compliance and to maintain product quality. Most medical devices will require some form of QMS; the complexity of the QMS will vary based on the classification of the device. Risk management is critical to ensure a safe and effective medical device and is referenced in section 7.1 of ISO 13485:2016.

Why is regulatory compliance important in QMS software?

Regulatory compliance in QMS software is critical as it ensures medical device companies adhere to global standards, minimizes the risk of penalties and enhances product safety and efficacy. Almost every major market requires the implementation and maintenance of a quality management system as a condition of product registration. Device manufacturers in Europe follow the ISO 13485 standard, US companies comply with the US FDA’s Quality System Regulation (QSR). So compliance is key to being legal and consumer trust.

How does AI in QMS software improve decision making?

AI in QMS software improves decision making by streamlining regulatory compliance and improving product quality, so you can make informed decisions faster.

What should I consider when choosing QMS software?

When choosing QMS software consider regulatory compliance, integration, AI and customer support. These will ensure the software works for your company.

How does QMS software improve document review?

Share this

You May Also Like

These Related Stories

QMS Software for Pharmaceutical Manufacturers

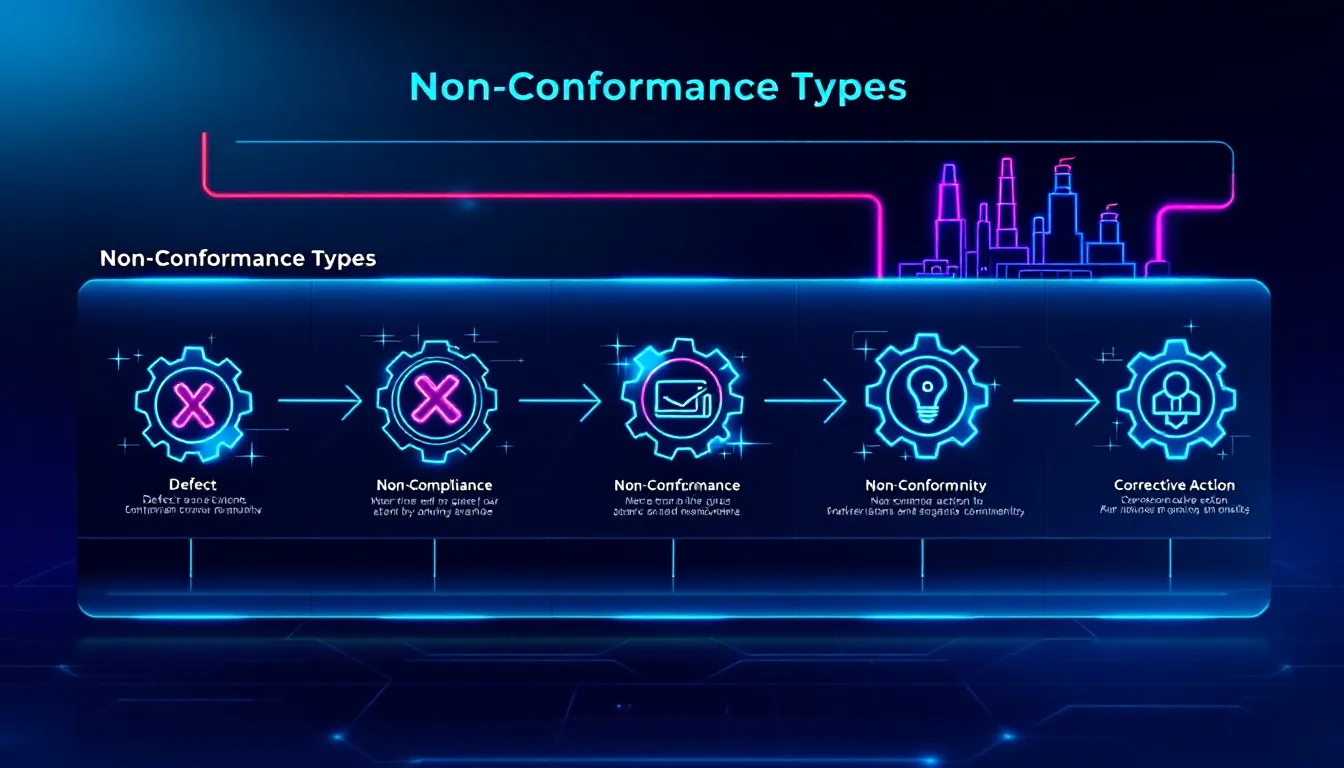

Mastering the Non Conformance Management Process: Steps and Strategies

No Comments Yet

Let us know what you think