Opcenter Execution

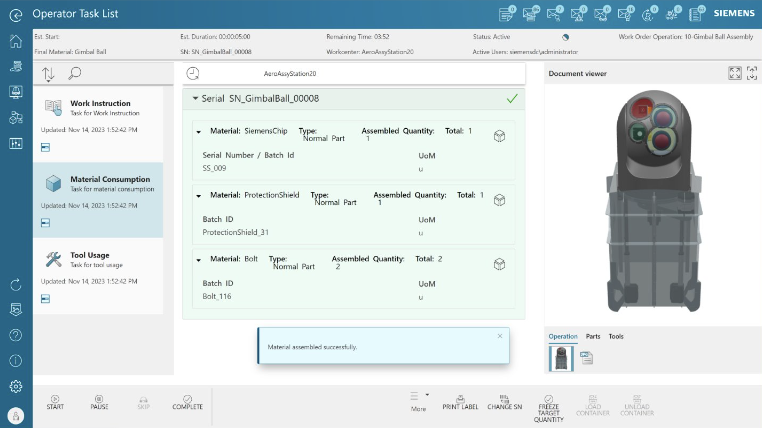

Opcenter Execution drives continuous improvement in manufacturing by integrating and analyzing real-time data, enabling manufacturers to monitor and optimize operations.

It identifies inefficiencies, supports corrective actions, and facilitates process refinement, reducing waste and improving product quality continuously.

What is Opcenter Execution?

Opcenter Execution, formerly known as Camstar MES, is a powerful software solution that helps manufacturers optimize their production processes, enhance product quality, and increase operational efficiency across the shop floor.

Enhanced Manufacturing With Opcenter Execution

Through its advanced features like optimized sequencing and resource allocation, Opcenter Execution significantly reduces cycle times while synchronizing production processes.

This holistic approach not only tracks production status, regulatory compliance, and quality requirements but also monitors equipment and personnel performance, driving continuous improvement and operational excellence.

Whether it's ensuring the flexibility needed in discrete manufacturing or managing the complexity of process manufacturing, this solution enhances product quality, accelerates delivery times, and optimizes production performance, setting a new benchmark for smart manufacturing.

Opcenter Execution Reviews

Key Advantages of Opcenter Execution

Enhances Production Efficiency

Opcenter Execution streamlines manufacturing workflows, significantly reducing production time and increasing throughput.

Improves Product Quality

It integrates quality management directly into production processes, ensuring higher product standards and compliance.

Boosts Operational Visibility

Provides real-time insights into manufacturing operations, enabling better decision-making and agility.

Supports Compliance and Traceability

Facilitates detailed tracking and documentation, essential for regulatory compliance and quality assurance.

Reduces Operational Costs

By enhancing resource efficiency and reducing waste, it substantially lowers the costs associated with manufacturing operations.

Flexible and Scalable

Adapts to the unique needs of various manufacturing environments, supporting both small scale operations and global enterprises.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Implementing Opcenter Execution

Leveraging Opcenter Execution alongside existing Enterprise Resource Planning (ERP) systems bridges the gap between planned and actual production capabilities, offering precise control over manufacturing processes and the flexibility to adapt to changing demands.

What are the benefits of implementation?

Implementing Opcenter Execution with ERP, Product Lifecycle Management (PLM), Manufacturing Execution Systems (MES), and additional tools, streamlines production from start to finish. This synergy enhances operational transparency, facilitates the swift adjustment to new challenges, and drives overall manufacturing efficiency.

Signs you need Opcenter Execution

Transitioning to a unified Manufacturing Execution System can significantly improve your production environment. Watch for these definitive signs that it's time to integrate Opcenter Execution into your operations.

Increasing Production Delays

Consistently missing delivery targets due to production bottlenecks reveals a critical need for integration. Opcenter Execution can eliminate these bottlenecks by streamlining production processes, ensuring timely deliveries and satisfied customers.

Lack of Real-time Visibility

The inability to monitor live production status underlines the necessity for Opcenter Execution. This platform provides comprehensive oversight across manufacturing operations, enabling decision-makers to respond swiftly to any issues that arise.

Inefficient Resource Utilization

Identifying resources that are frequently idle or overburdened points to a significant inefficiency within production operations. Opcenter Execution optimizes resource allocation, ensuring that every asset is used effectively to maximize productivity and reduce waste.

Quality Compliance Issues

Facing frequent quality non-conformances or compliance failures highlights the need for integrated quality control measures. Opcenter Execution addresses these challenges head-on, implementing stringent quality checks that uphold standards and ensure product integrity.

Inability to Scale Operations

When existing systems hinder growth and scalability, it’s clear that a more flexible and scalable solution is needed. Opcenter Execution provides the necessary infrastructure to support expansion efforts, offering scalable solutions that grow with your business.

Difficulty Tracking Production History

If a plant struggles to track products from raw materials to finished goods, it likely has traceability issues. Opcenter Execution resolves this by creating a real-time digital trace of each manufacturing step for full visibility and easy access to product histories.

Partner With Us To Reduce Your Technical Debt

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Opcenter Execution Products

.jpg?width=370&height=208&name=Opcenter%20APS%20(1).jpg)

Opcenter Execution Discrete

Opcenter Execution Discrete optimizes complex assembly processes in discrete manufacturing, offering advanced BOM management and real-time change adaptability while integrating quality control measures for product excellence.

.jpg?width=370&height=208&name=Opcenter%20Execution%20(1).jpg)

Opcenter Execution Process

Opcenter Execution Process provides unmatched traceability and efficiency in formula-based manufacturing for process industries, featuring comprehensive batch control, integrated quality testing, and seamless LIMS integration.

Opcenter Execution Electronics

Opcenter Execution Electronics caters to PCB and electronic assembly needs, facilitating high-quality production outcomes with rapid NPI, detailed production capacity optimization, and full product traceability.

Opcenter Execution Medical Device and Diagnostics

Opcenter Execution Medical Device is customized for the medical device and diagnostics sector, ensuring compliance, efficiency, and quality with error-proof manufacturing processes, regulatory compliance automation, and electronic device history records.

Opcenter Execution Pharma

Opcenter Execution Pharma enhances pharmaceutical manufacturing, prioritizing compliance and efficiency through paperless batch record management, compliant execution tracking, and master batch record integration.

.jpg?width=370&height=208&name=Opcenter%20Connect%20(1).jpg)

Opcenter Execution Semiconductor

Opcenter Execution Semiconductor serves the semiconductor industry, offering detailed tracking, analysis, and optimization for manufacturing, including throughput and yield optimization, advanced data analytics, and device-level traceability.

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

How is a Gantt Chart Used in Manufacturing Process?

.png)

Top Advantages of Laboratory Automation Systems

.png)

What Is A Bidirectional LIMS?

Frequently Asked Questions

Have Question? We are here to help

Can Opcenter Execution be tailored to specific industry needs?

Absolutely, Opcenter Execution is highly adaptable, offering configurations and customizations to meet the unique challenges and requirements of various manufacturing sectors.

What are the key benefits of implementing Opcenter Execution?

Implementing Opcenter Execution brings numerous advantages, including enhanced production efficiency, improved product quality, increased operational visibility, and better compliance management.

Is Opcenter Execution suitable for small to medium-sized enterprises?

Yes, Opcenter Execution is scalable and can be effectively deployed in both small and medium-sized enterprises, providing them with tools previously only accessible to larger companies.

How does Opcenter Execution ensure product quality?

It ensures product quality through integrated quality management features that monitor every stage of production, from initial design to final delivery.

Does Opcenter Execution support real-time decision-making?

Yes, it offers real-time data and analytics capabilities, empowering managers to make immediate, informed decisions to optimize production.

What industries benefit most from Opcenter Execution?

Industries like automotive, electronics, pharmaceuticals, and aerospace find great value in Opcenter Execution due to its comprehensive and versatile manufacturing management features.

How does Opcenter Execution handle production changes?

It allows for flexible adjustment of production schedules and processes in response to changes, ensuring minimal disruption and maximum efficiency.

Siemens Opcenter Execution

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter Execution.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)