Opcenter Intelligence

Opcenter Intelligence is a comprehensive manufacturing intelligence solution that transforms manufacturing data into actionable insights to improve decision-making and operational efficiency.

What is Opcenter Intelligence?

Opcenter Intelligence is a dynamic manufacturing intelligence solution designed to elevate operational efficiency and decision-making. By aggregating and contextualizing manufacturing data, it provides actionable insights for manufacturers to enhance process control. Leveraging advanced data analytics, Opcenter Intelligence transforms raw data from IoT devices and production systems into meaningful information, guiding strategic operational improvements.

Enhanced Manufacturing With Opcenter Intelligence

Opcenter Intelligence revolutionizes manufacturing with data-driven insights and real-time analysis, empowering decision-makers to optimize processes, enhance quality, and drive continuous improvement.

By identifying root causes for quality issues and resource bottlenecks, Opcenter Intelligence paves the way for targeted improvements and process optimizations, ensuring long-term sustainability and profitability.

Opcenter Intelligence Reviews

Key Advantages of Opcenter Intelligence

Quality Enhancement

Enhance product quality by boosting first-pass yield, minimizing scrap, and swiftly pinpointing the underlying causes of quality issues.

Efficiency Enhancement

Drive productivity gains by optimizing overall equipment effectiveness (OEE), streamlining throughput, and maximizing resource utilization.

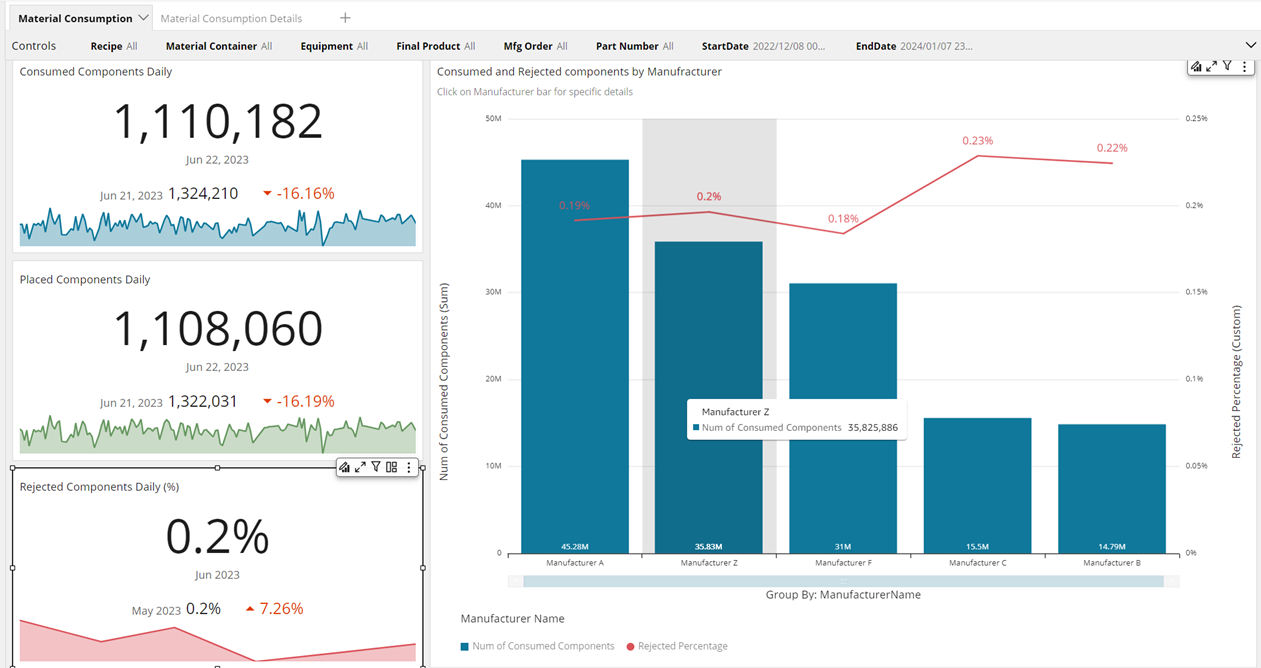

Data Visualization and Interpretation

Transform scattered manufacturing data into coherent, meaningful insights by consolidating and organizing information from diverse sources.

Predictive Maintenance Insights

Anticipate equipment failures and optimize maintenance schedules by analyzing historical data patterns, reducing downtime, and enhancing operational efficiency.

Actionable Intelligence Generation

Utilize advanced analytics and collaborative approaches to convert raw data into actionable intelligence, empowering stakeholders at all levels of the organization to make informed decisions.

Real-time Performance Monitoring

Gain instant insights into machine, line, and plant performance through the integration of manufacturing operations management (MOM) and Internet of Things (IoT) data.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Implementing Opcenter Intelligence

Opcenter Intelligence connects critical manufacturing data from various sources within the manufacturing environment, including Manufacturing Execution Systems (MES), Manufacturing Operations Management (MOM), the Industrial Internet of Things (IoT), and other manufacturing data sources. This creates a unified platform where all critical data is accessible in real time.

What are the benefits of implementation?

Opcenter Intelligence's advanced data analytics turns enormous amounts of raw data into actionable insights. It provides comprehensive visibility with tailored dashboards that display key performance indicators (KPIs) derived from both real-time and historical plant data, enabling precise monitoring and decision-making.

Signs You Need Opcenter Intelligence

Leveraging Opcenter Intelligence can transform your manufacturing data into strategic insights, driving efficiency and innovation. Here are signs indicating the need for such integration:

Inconsistent Data Analysis

If making sense of your data feels like deciphering a complex puzzle due to inconsistencies and inaccuracies, Opcenter Intelligence can harmonize and contextualize your data for clearer insights.

Lack of Real-Time Operational Visibility

Struggling to gain immediate insights into production performance? Opcenter Intelligence offers dashboards for real-time visibility, crucial for prompt and informed decision-making.

Quality Control Challenges

Encountering recurring quality issues or failing to identify their root causes quickly means you could benefit from the predictive analytics and quality optimization features of Opcenter Intelligence.

Predictive Maintenance Gaps

If unexpected machine downtime is a common obstacle, the predictive maintenance capabilities provided by Opcenter Intelligence can forecast and mitigate potential failures.

Compliance and Standardization Issues

Difficulty in maintaining or proving compliance with industry standards suggests a need for the structured and detailed data management Opcenter Intelligence provides.

Slow Adaptation to Market Demands

If your production processes can't swiftly adapt to changing market demands, integrating Opcenter Intelligence could equip your operations with the required agility and foresight.

Partner With Us To Reduce Your Technical Debt

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Opcenter Intelligence Products

Opcenter Intelligence Cloud

Our platform offers cloud-based data and analytics for global visibility and web-based production insights, including features like global data accessibility and smart data transformation for continuous improvement in production optimization.

.jpg?width=370&height=208&name=Opcenter%20Execution%20(1).jpg)

Opcenter Intelligence AOI FCR

Our solution leverages AI for enhanced AOI processes, reducing false calls and improving first-pass yield through AI-powered analysis and efficient inspection, alongside cloud-based AI training for streamlined model development.

Opcenter Intelligence Component Analytics

Our solution uses AI to detect component issues in real-time, ensuring only verified parts are used in production, with features including immediate identification of compromised components, AI-based authentication of production images, and comprehensive traceability of all used parts.

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

Why Manufacturers Struggle to Use Data — and How Data Integration Fixes It

How is a Gantt Chart Used in Manufacturing Process?

.png)

Top Advantages of Laboratory Automation Systems

Frequently Asked Questions

Have Question? We are here to help

How does Opcenter Intelligence differ from traditional data analysis tools?

Unlike basic tools, Opcenter Intelligence integrates with manufacturing operations management (MOM) and IoT data for real-time insights, utilizing AI for deeper analysis.

Can Opcenter Intelligence integrate with existing manufacturing systems?

Yes, it's designed to harmonize with existing ERP, MES, and other systems, enhancing data coherence and providing a unified operational view.

What kind of manufacturing data can Opcenter Intelligence handle?

It processes both big and fast data from various sources, including machine performance, quality metrics, and production efficiency indicators.

Who can benefit from implementing Opcenter Intelligence?

Manufacturers aiming to leverage AI for data-driven optimization in production quality, efficiency, and global operational visibility will find it particularly beneficial.

Is Opcenter Intelligence suitable for small and medium-sized enterprises?

Its scalable nature allows SMEs to leverage powerful analytics and improve their operations without extensive IT infrastructure.

How does Opcenter Intelligence support predictive maintenance?

By analyzing real-time and historical data, it identifies potential equipment failures before they occur, reducing unplanned downtime.

Can Opcenter Intelligence improve production quality?

Yes, it identifies quality issues' root causes, enhancing first-pass yield and reducing waste and rework.

Does Opcenter Intelligence offer any cloud-based solutions?

Opcenter Intelligence Cloud provides cloud-based access to analytics and data, facilitating global visibility and operational insights.

Siemens Opcenter Intelligence

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter Intelligence.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)