Opcenter RD&L

Opcenter RD&L is tailored to enhance the efficiency of research, development, and laboratory workflows, particularly in consumer packaged goods industries. It boosts innovation and improves the management of complex data.

What is Opcenter RD&L?

Opcenter RD&L is Siemens' comprehensive solution for streamlining and optimizing research, development, and laboratory processes within manufacturing, promoting innovation and efficiency.

Enhanced Manufacturing With Opcenter RD&L

The platform consolidates R&D data into a single repository, improving specification management and minimizing inconsistencies.

This centralization enhances team collaboration and allows for direct supplier involvement in product development, enabling them to input material specifications directly into our system.

Opcenter RD&L simplifies product development through virtual simulation and testing of new products, significantly reducing the need for physical prototypes.

Opcenter RD&L Reviews

Key Advantages of Opcenter RD&L

Enhanced Quality Control

Integrate laboratory information to improve product quality and compliance from the start.

Improved Collaboration

Foster better communication and data sharing across R&D teams and departments.

Accelerated Innovation

Speed up the product development cycle with comprehensive data analysis and management tools.

Digital Twin Simulation

Utilize digital twins for efficient formula testing and modification, minimizing the need for physical trials.

Reduced Complexity

Simplify the R&D process with a centralized system of information and streamlined workflow management.

Compliance and Standardization

Ensure products meet regulatory requirements with the support of automated compliance checks.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Implementing Opcenter RD&L

Traditional R&D processes often lack the cohesive data and workflow management needed to navigate today’s complex product development landscape. Without a unified system, tracking progress and ensuring compliance becomes tedious, slowing down innovation.

What are the benefits of implementation?

B implementing Opcenter RD&L solutions with ERP, PLM, MES, and other tools, you establish a unified platform that streamlines research, development, and laboratory operations. This harmonization not only simplifies data management but also fosters collaboration across teams, ensuring that every phase of product development is aligned and optimized for efficiency, quality, and compliance.

Signs You Need Opcenter RD&L

Understanding when to embrace Opcenter RD&L is crucial for elevating your R&D efficiency and innovation. The transition to an integrated RD&L system could be the turning point for your manufacturing operations. Look out for these unmistakable signs that suggest it's time to consider integrating Opcenter RD&L into your processes.

Process Disconnection

Process disconnections stem from communication gaps in research, development, and laboratory operations. Opcenter RD&L resolves these issues by offering a unified platform that boosts collaboration across engineering, sales, and production.

Escalating R&D Expenditures

Continuous increases in R&D costs without corresponding value or returns suggest inefficiencies in processes or resource management. Opcenter RD&L provides a framework for cost-effective R&D activities, optimizing resource use and reducing waste to align expenses with outcomes.

Compliance Challenges

Navigating regulatory complexities can be daunting, especially when struggling to keep up with evolving standards. Opcenter offers an integrated solution to mitigate these challenges, using automated compliance checks to ensure adherence to industry regulations.

Laboratory Inefficiencies

Timely and accurate lab results are crucial for R&D success. If lab results are frequently delayed or inaccurate, it indicates underlying inefficiencies. Opcenter RD&L integration optimizes lab operations, from sample management to result analysis, ensuring high-quality, reliable outputs for customers.

Collaboration Hurdles

Effective collaboration is vital for innovative R&D. When teams face difficulties sharing and working on data cohesively, it hampers efficiency and innovation. Opcenter RD&L fosters collaboration by centralizing data and processes, making information readily accessible to stakeholders, and enhancing synergy across projects.

Prolonged Product Development Cycles

If you're consistently experiencing delays in product development cycles, it's a sign that your current processes lack efficiency. Opcenter RD&L integration can compress these timelines, ensuring faster progress of the finished product from concept to completion through optimized planning and execution.

Partner With Us To Reduce Your Technical Debt

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)

Opcenter RD&L Products

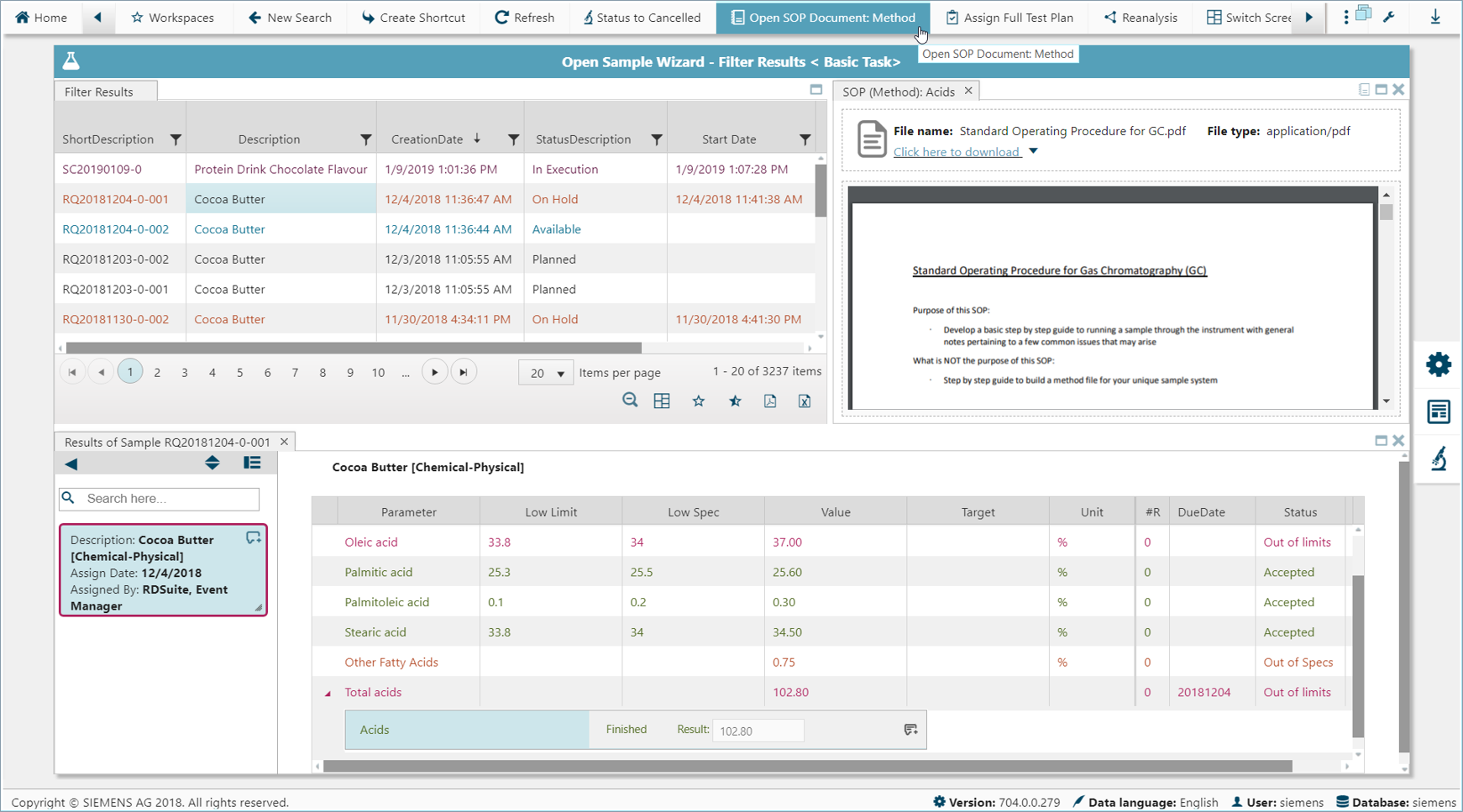

Opcenter Laboratory

Elevate and manage your lab's role in the R&D process with Opcenter Laboratory. This comprehensive software solution improves lab efficiency and assures product quality from the earliest stages of development.

Opcenter Formulation

Speed up the journey from concept to product with Opcenter Formulation. This tool allows you to quickly adjust and test product formulas, ensuring they’re market-ready sooner.

Opcenter Specification

With Opcenter Specification, you have a single source for all the data needed for your raw materials, finished goods, and packaging specifications, making your product specification and development process more precise and efficient.

From Our Blog

Stay up to date with what is new in our industry, learn more about the upcoming products and events.

How is a Gantt Chart Used in Manufacturing Process?

.png)

Top Advantages of Laboratory Automation Systems

.png)

What Is A Bidirectional LIMS?

Frequently Asked Questions

Have Question? We are here to help

How does Opcenter RD&L improve time to market?

By streamlining the development process and enabling quicker decision-making through real-time data and simulations, Opcenter RD&L significantly reduces the time required to bring new products to market.

How does Opcenter RD&L facilitate collaboration?

It enhances collaboration by providing a unified platform where R&D, laboratory staff, and production teams can access shared data, communicate changes, and update processes in real-time.

How does digital twin technology work within Opcenter RD&L?

Digital twin technology allows for virtual testing and simulation of products, enabling the exploration of design and process changes without physical prototypes, saving manufacturers time and resources.

What is the difference between LIMS and MES?

Laboratory Information Management Systems (LIMS) focus on managing data, tests, and results in laboratory settings, streamlining processes like tracking samples and ensuring compliance with standards. Manufacturing Execution Systems (MES) coordinate and control all aspects of the manufacturing execution process from the shop floor to equipment and resources, optimizing production efficiency and quality.

What are the key features of Opcenter Laboratory?

Key features include comprehensive sample management, quality control analytics, seamless integration with R&D processes, and robust data analysis capabilities to enhance laboratory efficiency.

Can Opcenter RD&L manage complex formulas?

It excels in managing and optimizing complex formulas, thanks to its advanced simulation and formula management capabilities, ensuring product quality and efficiency.

How does Opcenter RD&L support compliance?

It ensures compliance by facilitating detailed documentation of product data, automating compliance checks, and maintaining a central repository for all regulatory data, significantly simplifying adherence to global standards.

What is specification management software?

Specification management software is a tool designed to organize and control all the detailed information and documentation regarding the specifications of products, raw materials, and processes within the supply chain of an organization.

What industries benefit most from Opcenter RD&L?

Industries that involve complex product development, such as pharmaceuticals, chemicals, and consumer goods, find great business value in Opcenter RD&L for its comprehensive data management solutions and process optimization features.

Siemens Opcenter RD&L

Snic Solutions is recognized as one of the elite organizations partnered with Siemens as a value-added reseller of Opcenter RD&L.

/About%20Page/Blake%20Digital%20Transformation%20Solutions.png?width=500&height=500&name=Blake%20Digital%20Transformation%20Solutions.png)