Benchmarking in manufacturing is the process of comparing your company’s operations, processes, and metrics against industry bests or leading firms in the same sector.

In this article, we will explore the different types of benchmarking, their benefits, and how to implement an effective benchmarking process in your manufacturing operations.

Key Takeaways

-

Benchmarking in manufacturing involves comparing performance metrics against industry leaders to drive operational excellence and identify improvement areas.

-

There are various benchmarking types, including internal, competitive, performance, functional, and generic benchmarking, each serving unique purposes for evaluating operations.

-

Successful benchmarking requires a structured approach, including selecting relevant metrics, accurate data collection, and setting realistic goals to enhance efficiency and drive continuous improvement.

Understanding Benchmarking in Manufacturing

Benchmarking involves comparing performance metrics to those of industry leaders. It often includes analysis against best-in-class businesses. In the manufacturing industry, the focus has shifted from merely evaluating product metrics to a more comprehensive analysis that includes process and business metrics. Evaluating performance metrics helps companies identify areas for improvement and set realistic growth goals. This shift allows manufacturing companies to gain deeper insights into their operations and identify areas for improvement.

Benchmarking is vital for manufacturers as it offers insights from successful competitors and accelerates organizational learning. Continuous assessment of performance shows manufacturers where they stand in the market. Nevertheless, challenges such as variability in key measure definitions can arise.

Companies like Reata Engineering leverage benchmarks for ongoing performance assessments and continuous improvement efforts. Continuous improvement is essential for staying competitive in the global manufacturing marketplace. Despite these challenges, benchmarking remains a powerful tool for achieving operational excellence and maintaining a competitive edge in the manufacturing industry.

Types of Benchmarking in the Manufacturing Environment

Manufacturers utilize various benchmarking methods to evaluate their operations, each offering unique insights and advantages. Understanding the different types of benchmarking can help manufacturing businesses select the most appropriate method for their specific needs. The primary types of benchmarking in the manufacturing environment include:

-

Internal benchmarking

-

Competitive benchmarking

-

Performance benchmarking

-

Functional benchmarking

-

Generic benchmarking

Internal benchmarking allows manufacturers to compare performance across different departments or product lines within the same organization. Competitive benchmarking involves comparing manufacturing processes and metrics with industry competitors to identify strategic advantages.

There are three types of benchmarking:

-

Performance benchmarking: focuses specifically on measuring performance metrics such as production efficiency and quality against recognized standards.

-

Functional benchmarking: looks at processes and best practices from industries that excel in similar functions.

-

Generic benchmarking: involves comparing processes and metrics irrespective of the industry.

Performance Benchmarking

Performance benchmarking in manufacturing is a comparative assessment of performance relative to competitors and industry standards. This method involves assessing metrics such as production rates and quality against those of industry leaders. Regular comparison of business performance indicators with industry standards helps manufacturers spot performance gaps and areas for improvement.

The primary purpose of performance benchmarking is to establish a consistent feedback loop to optimize performance and efficiency. This process not only reveals weak links in operations but also drives accountability, competitiveness, and profitability. Understanding their position relative to industry leaders allows manufacturers to set realistic goals and devise strategies for better operational efficiency and productivity.

Benchmarking provides valuable insights that drive competitive advantage and shape organizational goals. For instance, a manufacturer might discover that their production rates are lower than industry standards, prompting them to investigate and address the root causes. This continuous cycle of measuring, comparing, and improving ensures that manufacturers stay competitive and achieve operational excellence.

Competitive Benchmarking

Competitive benchmarking helps manufacturers understand their standing in the market by comparing their processes and performance metrics with peers. This method provides insights that help companies gain a competitive advantage by highlighting their strengths and weaknesses. To effectively benchmark against competitors, it is crucial to define what performance information to gather and how to use it for meaningful comparison.

Analyzing benchmarking data from competitors helps manufacturers pinpoint areas of lag and devise improvement strategies. This process helps companies stay competitive, enhance operational efficiency, and achieve operational excellence. For example, a manufacturer might discover that a competitor has a more efficient production process, prompting them to adopt similar best practices to improve their own operations.

Internal Benchmarking

Internal benchmarking allows organizations to compare different departments or product lines to identify performance discrepancies and improvement areas. This method is particularly useful for large manufacturing companies with multiple divisions or product lines, as it helps to ensure consistency and operational excellence across the organization.

Leveraging internal benchmarking data enables manufacturers to recognize and apply best practices across the organization. Customer feedback is a critical benchmark that reflects the experience of those receiving services or products. This process fosters a culture of continuous improvement and helps companies stay competitive in the manufacturing industry.

For instance, a company might find that one department has significantly higher productivity rates, leading them to investigate and replicate the successful practices across other employees departments.

Key Benefits of Benchmarking for Manufacturers

Benchmarking offers numerous benefits for manufacturers, including:

-

Enhanced operational efficiency by comparing processes with industry standards

-

Identification and elimination of inefficiencies, leading to notable cost savings and reduced waste

-

Uncovering cost-saving opportunities

-

Maintaining high product quality by ensuring outputs meet or exceed market expectations

Another key benefit of benchmarking is the establishment of a reliable feedback mechanism that aids in critical decision-making. Consistent benchmarking efforts provide manufacturers with first-hand statistics about industry performance, helping them evaluate their operational strengths and weaknesses. This ongoing process of measuring, comparing, and improving fosters a culture of continuous improvement within the organization.

Ultimately, the primary aim of benchmarking is to enhance efficiency, quality, and profitability by analyzing performance metrics. Setting performance targets based on industry standards enables manufacturers to enhance quality control, reduce defect rates, and boost customer satisfaction. For example, a company might benchmark its logistics operations against top performers in the industry, leading to improved delivery times and higher customer satisfaction.

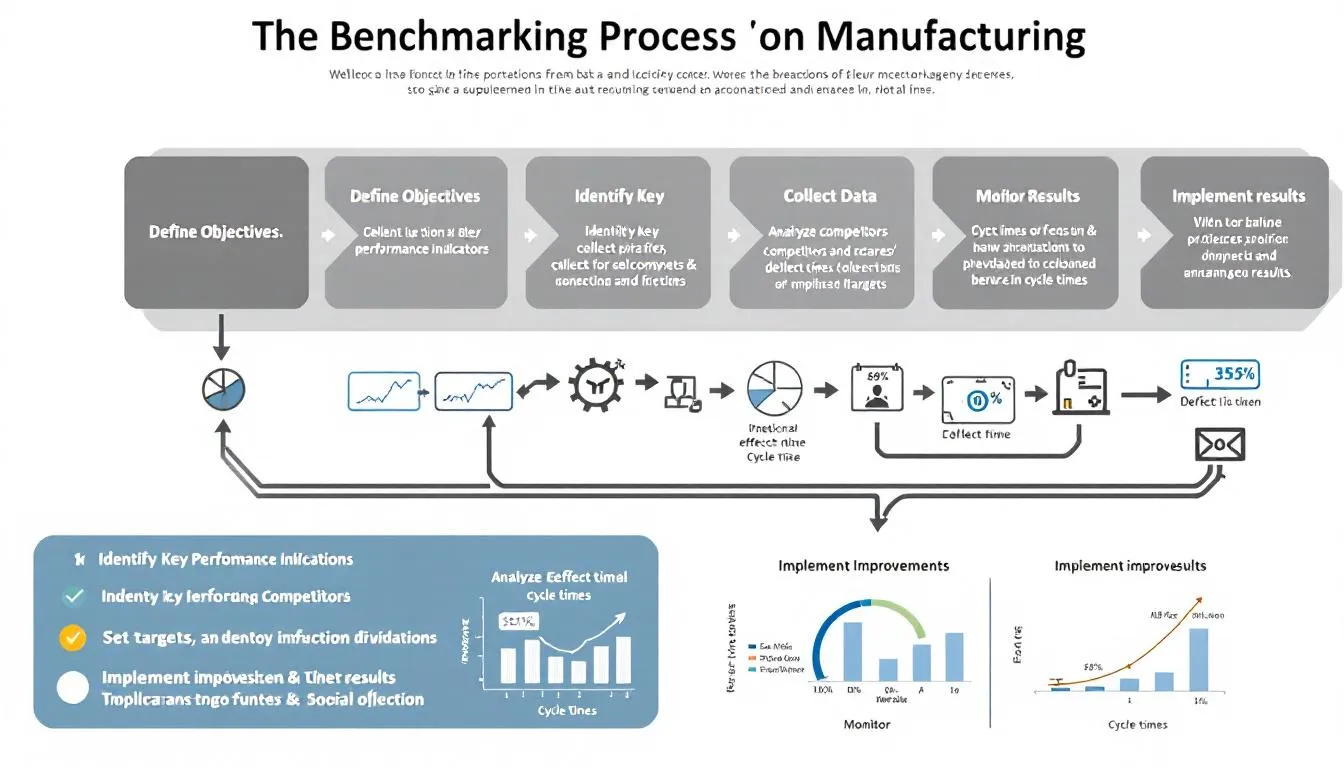

How to Implement a Successful Benchmarking Process

Implementing a successful benchmarking process in manufacturing requires a structured approach that compares performance against industry standards to identify areas for enhancement. The first step is to choose benchmarking methods that align with the specific organizational needs and challenges. Embarking on continuous improvement requires a gradual incorporation of streamlined processes over time. This ensures that the benchmarking process provides meaningful and actionable insights for the business.

Successful benchmarking hinges on:

-

Selecting metrics that provide a clear view of operational performance across various categories.

-

Establishing baseline performance levels.

-

Setting improvement targets based on industry benchmarks.

The results from a benchmarking initiative can provide manufacturers with valuable statistics about industry performance, aiding in the evaluation of their operational strengths and weaknesses.

Identifying Key Performance Indicators (KPIs)

Selecting relevant KPIs is crucial for meaningful benchmarking outcomes. These indicators should reflect both the business strategy and the standards of the industry. By identifying key performance indicators that align with the organization’s strategic goals, manufacturers can ensure that their benchmarking efforts are focused on areas that will drive the most significant improvements.

KPIs serve as the foundation for the benchmarking process, guiding manufacturers in measuring and comparing their performance against industry standards. For instance, a manufacturer might select KPIs related to production efficiency, quality control, and customer satisfaction. These metrics provide valuable insights into the organization’s performance and help identify areas for improvement.

Collecting and Analyzing Benchmarking Data

Accurate data collection processes are fundamental to effective benchmarking and revealing areas for improvement. Data collection methods must be reliable and systematic to ensure the accuracy of benchmarking analyses. Measuring problems against set goals allows manufacturers to identify gaps between their current state and the ideal future state.

Once the data is collected, it must be thoroughly analyzed to:

-

Identify performance gaps and areas for improvement

-

Help manufacturers understand where they stand in comparison to industry standards

-

Develop strategies for identifying gaps to enhance their operations

For example, a manufacturer might analyze their production data to identify bottlenecks and implement changes to improve efficiency.

Setting Realistic Goals and Implementing Strategies

Achievable targets derived from benchmarking insights help organizations develop concrete strategies for improvement. This process involves:

-

Setting realistic goals based on benchmarking findings to create actionable strategies

-

Focusing on areas with the most potential for improvement

-

Implementing best practices to achieve operational excellence

These steps ensure that the organization can lead to significant performance improvements and implement strategies for success.

By setting realistic goals, manufacturers can ensure that their strategies are both practical and effective. For example, a company might set a goal to reduce production costs by 10% over the next year based on benchmarking data. This goal would then guide the development of specific strategies and initiatives to achieve the desired outcome.

Best Practices for Effective Benchmarking

Involving all stakeholders in benchmarking enhances the quality of insights and encourages shared ownership of the improvement process. Collaborating internally and externally enhances the identification of new ideas for operational improvement. By involving stakeholders from all levels, manufacturers can gain a comprehensive view of processes and identify improvement opportunities. This collaborative approach ensures that the benchmarking process is thorough and that the resulting strategies are well-supported throughout the organization.

Leading manufacturers often standardize their measurement approaches to ensure consistency and reliability in benchmarking data. Incorporating technology, such as ERP systems, enables real-time tracking and analysis of performance metrics, enhancing the effectiveness of benchmarking efforts.

Regular and structured review cycles of benchmarking data are crucial for driving timely continuous improvement within manufacturing operations.

Summary

Benchmarking is an invaluable tool for manufacturers seeking to enhance their operational efficiency, reduce costs, and improve product quality. By comparing their performance metrics against industry standards and best practices, manufacturers can identify areas for improvement and develop strategies to achieve operational excellence. The key benefits of benchmarking include enhanced operational efficiency, cost reduction, continuous improvement, and increased customer satisfaction.

Implementing a successful benchmarking process requires a structured approach, including selecting relevant KPIs, accurate data collection and analysis, and setting realistic goals. By involving all stakeholders and leveraging technology, manufacturers can ensure the effectiveness of their benchmarking efforts. Ultimately, benchmarking fosters a culture of continuous improvement, helping manufacturers stay competitive and achieve their business goals.

Frequently Asked Questions

What is benchmarking in manufacturing?

Benchmarking in manufacturing involves comparing performance metrics against industry leaders to identify improvement opportunities and enhance operational excellence. This practice is crucial for staying competitive and achieving superior results.

What are the different types of benchmarking in the manufacturing environment?

The different types of benchmarking in manufacturing are internal benchmarking, competitive benchmarking, performance benchmarking, functional benchmarking, and generic benchmarking. Each type serves to identify best practices and improve operational efficiency within the manufacturing process.

How can benchmarking benefit manufacturing companies?

Benchmarking significantly benefits manufacturing companies by enhancing operational efficiency, reducing costs, and fostering continuous improvement while simultaneously improving product quality and customer satisfaction. This systematic comparison with industry standards drives overall performance enhancement.

What are key performance indicators (KPIs) in the context of benchmarking?

KPIs serve as essential metrics that align with an organization's strategic goals and industry standards, enabling effective benchmarking to pinpoint areas needing improvement. Their role is crucial in facilitating informed decision-making and enhancing overall performance.

How can technology enhance benchmarking efforts in manufacturing?

Technology significantly enhances benchmarking in manufacturing by providing real-time data analytics and automation, allowing for swift identification of underperforming areas and the implementation of necessary corrective actions. This leads to improved operational efficiency and performance.

Share this

You May Also Like

These Related Stories

Data Integration vs Data Virtualization

Ultimate Guide to Manufacturing Digital Transformation Roadmaps

No Comments Yet

Let us know what you think