If you’re wondering how to go paperless in manufacturing, this guide offers a clear, step-by-step approach.

We’ll cover everything from assessing your current processes to selecting the right software and digitizing documents.

Key Takeaways

-

Paperless manufacturing enhances operational efficiency by replacing paper with digital tools, reducing costs, and improving accuracy in data management.

-

Key benefits of transitioning to a paperless system include improved resource allocation, enhanced quality control, and better traceability of production activities.

-

Work orders, customer orders, and purchase orders are created and managed digitally in paperless manufacturing, streamlining operations and reducing manual errors.

-

Successful implementation involves assessing current processes, choosing the right software, digitizing documents, and fostering a change management culture to ensure employee adaptation.

Understanding Paperless Manufacturing

Paperless manufacturing is a process that eliminates paper documents and replaces them with digital tools and systems. This is to reduce manual data entry processes that are error prone and inaccurate. Traditional paper based systems are inaccurate with an accuracy rate of less than 99.5% and create blind spots that hampers responsiveness to demands and quality control in paperless factories. These traditional systems rely on paper travelers – physical documents that accompany products through the production process to record procedures and data. Paperless manufacturing eliminates paper documentation to improve data accessibility and security.

Going paperless is not just a technological upgrade, it’s a strategic imperative that gives you agility, efficiency and competitiveness. Going paperless helps you reduce costs on printing, storage and document loss and reduce environmental impact of excessive paper consumption. The digital revolution replaces paper with digital interfaces, real time data capture and analysis that improves decision making and operational efficiency. But going paperless requires a significant investment in hardware, software and training for personnel.

Advances in technology such as cloud computing, IoT connectivity and user friendly software interfaces has made paperless manufacturing possible and effective. Connected worker platforms replaces traditional paper based processes, gives instant access to resources and seamless flow of information across the manufacturing enterprise. These digital systems also allows integration and real time access to standard operating procedures so that instructions are always up to date and accessible. AI powered software is now part of production management and record keeping that further optimizes manufacturing operations. Digital solutions includes cloud based software, mobile/wearable technology and advanced analytics for manufacturing processes. Paperless manufacturing uses digital tools like tablets, sensors and software applications to capture operations data.

In a paperless factory, digital tools like electronic forms captures data and information electronically, replaces tedious paperwork. Digitizing skills tracking and performance assessments also improves workforce management so that employees are equipped to work in a paperless environment. This not only simplifies operations but also fosters a culture of continuous improvement and innovation in the manufacturing industry.

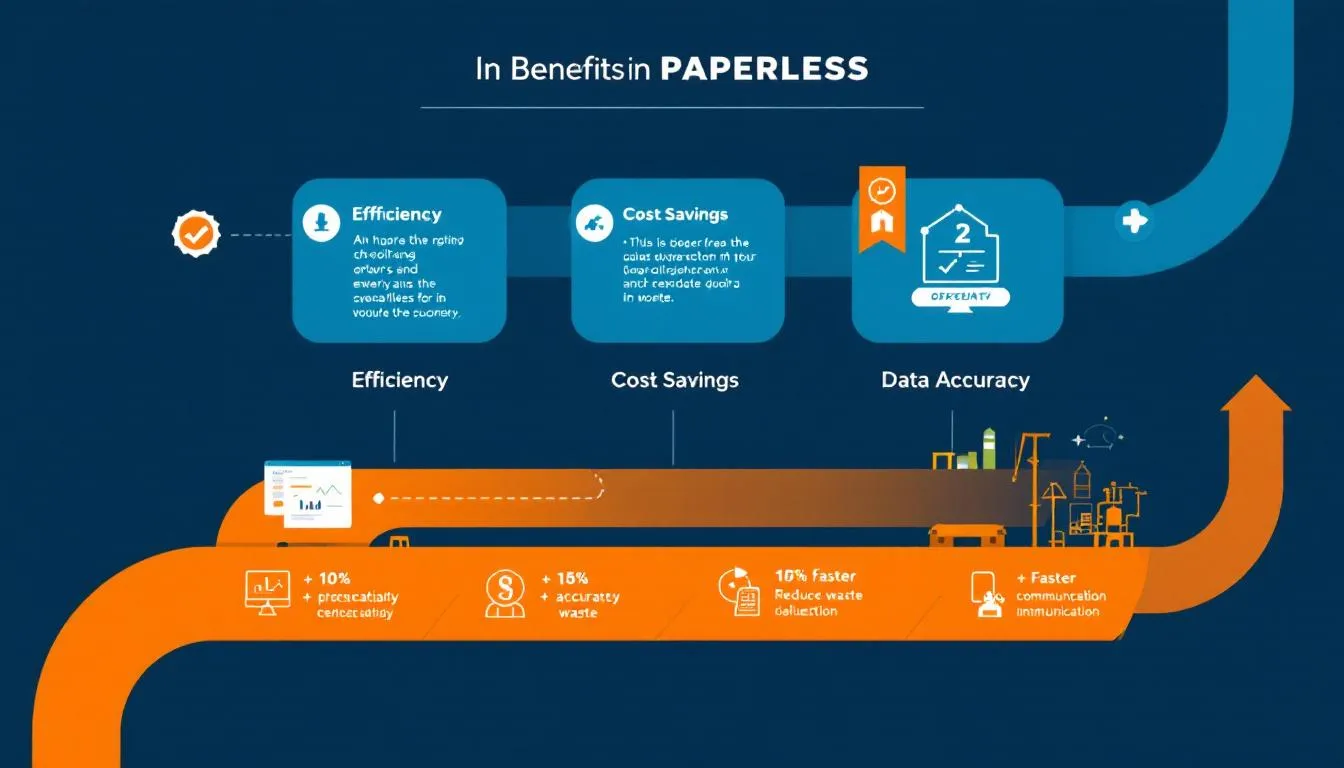

Key Benefits of Going Paperless in Manufacturing

Transitioning to a paperless manufacturing system offers a plethora of benefits that can significantly enhance the overall efficiency and productivity of manufacturing operations. Key advantages include:

-

Substantial cost savings by eliminating expenses tied to printing, storage, and manual handling of paper documents.

-

More effective allocation of resources.

-

Nearly half of manufacturers believe that eliminating paper would lead to significant productivity improvements.

-

Resulting in more streamlined operations.

Another key benefit of going paperless is enhanced quality control, which includes:

-

Digital tools and dashboards providing real-time visibility into key performance metrics, enabling quicker and better-informed decision-making.

-

Real-time access to production data ensuring that any quality issues are promptly identified and addressed, leading to improved product quality and customer satisfaction.

-

Deployment of digital tools in paperless manufacturing leading to error proofing and real-time notifications of quality issues, further enhancing the reliability of manufacturing processes.

-

Quality control software ensures that products meet quality standards and can help in the identification of defects, further supporting enhanced quality control efforts.

Steps to Implement Paperless Manufacturing

Implementing paperless manufacturing requires a strategic and systematic approach to ensure a smooth transition. The journey begins with assessing current processes to identify areas where digital solutions and digital thread can be most effectively applied. All employees should be encouraged to use the paperless software for all relevant processes to ensure maximum benefit.

Next, selecting the right paperless manufacturing software is crucial for maximizing efficiency and streamlining operations. Finally, digitizing existing documents is essential to fully transition to a paperless environment. These steps, when executed meticulously, pave the way for a successful and sustainable paperless manufacturing system.

Assess Current Processes

The first step in transitioning to paperless manufacturing is to assess current production processes and identify specific areas where digital solutions can be implemented. This evaluation is critical as it helps pinpoint inefficiencies and areas that are most prone to errors in the existing paper-based system. This includes identifying the use of paper travelers, which are physical documents used to track procedures and data throughout the facility. By thoroughly understanding the current state of operations, manufacturers can develop a targeted plan to streamline processes and enhance productivity.

Implementing a digital document management system is a crucial initial step in this assessment phase. This system helps organize and manage all existing paper documents, providing a complete picture and making it easier to transition to digital formats.

Identifying and prioritizing areas for digital implementation ensures a smoother transition to a paperless manufacturing environment, ultimately improving operational efficiency and reducing reliance on paper-based processes.

Choose the Right Paperless Manufacturing Software

Choosing the right paperless manufacturing software is essential for the successful implementation of a paperless system. When selecting software, it is important to consider its compatibility with existing systems and the overall user experience. For instance, the MachineMetrics system can be easily integrated via API with ERP and MRP systems and quality management software, ensuring seamless connectivity and data flow across the manufacturing enterprise.

To maximize efficiency, manufacturers should conform to the business processes of the software instead of customizing it extensively. This approach ensures that the software’s inherent efficiencies are fully utilized, leading to streamlined operations and reduced complexity.

Selecting suitable paperless manufacturing software that aligns with the organization’s needs and existing infrastructure leads to significant improvements in efficiency and productivity.

Digitize Existing Documents

Digitizing existing paper documents is a crucial step in transitioning to a paperless manufacturing environment. Utilizing advanced tools like document management systems and scanners can facilitate the conversion of paper documents into digital formats. Tools like Augmentir’s AugieTM can enhance the efficiency of this process, ensuring that the digitization is thorough and accurate.

Transitioning to digital formats not only improves accessibility and reduces physical storage needs but also supports better data management. Digital documents can be easily searched, retrieved, and shared, leading to more efficient workflows and enhanced collaboration.

Moreover, digital tools like electronic signatures further streamline processes by eliminating the need for physical document handling and approval, making the entire production process more efficient and effective.

Enhancing Production Processes with Digital Tools

Enhancing production processes with digital tools is a key aspect of paperless manufacturing. By leveraging cloud-based software, advanced analytics, and IoT connectivity, manufacturers can replace traditional paper-based systems with more efficient and accurate digital solutions. These digital solutions streamline the entire production line, improving efficiency, accuracy, and collaboration throughout the manufacturing process. This transformation not only streamlines production activities but also enables real-time monitoring and analysis, leading to continuous improvement and optimized operations. Cloud-based systems enhance collaboration by allowing all team members to access real-time data, ensuring better coordination and decision-making across the enterprise.

The three main strategies to enhance production processes include automating data collection, integrating IoT and ERP systems, and utilizing mobile devices. Digital tools help manage and optimize production tasks, providing real-time visibility and accuracy for operators and workers on the shop floor.

Automate Data Collection

Automating data collection is a fundamental strategy in paperless manufacturing, as it increases accuracy while decreasing the time spent on data entry. By capturing data at the machine level, paperless manufacturing ensures accuracy and eliminates manual logging errors.

Methods for data capture include embedded devices in OEM equipment, sensors, and retrofitted devices on legacy equipment, all of which contribute to more reliable and consistent data collection.

Digital tracking systems in manufacturing monitor progress and track materials, effectively eliminating manual tracking and reducing the potential for errors and lost documents. The automation of data collection not only enhances data quality but also provides real-time visibility into tracking production activities, enabling quicker and more informed decision-making.

Integrate IoT and ERP Systems

Integrating IoT devices with ERP systems is another critical strategy for enhancing production processes in paperless manufacturing. IoT sensors provide real-time tracking of production processes and equipment performance, which increases productivity and extends value between the shop floor and enterprise systems. This integration facilitates real-time data and analytics, offering up-to-date order status, inventory visibility, and machine-level monitoring, thus enabling more informed decision-making and streamlined operations. Manufacturing Execution Systems (MES) provide real-time production scheduling and tracking, allowing for efficient workflow and better resource management.

The combination of IoT and an ERP system creates a digital connection that enhances traceability and efficiency throughout the manufacturing process. This internet connection ensures that all stakeholders have access to the same accurate and up-to-date information, leading to better coordination and optimized production workflows.

Utilize Mobile Devices

Mobile devices play a crucial role in paperless manufacturing by streamlining data collection and providing instant access to information directly from the shop floor. Applications on mobile devices allow workers to input and retrieve data efficiently, reducing the need for manual data entry and enhancing overall productivity. Interactive screens and internet connections further support the effective use of mobile devices and human machine interface systems, ensuring that real-time data is always accessible.

Utilizing mobile devices enhances flexibility and responsiveness in manufacturing operations, enabling manufacturers to access digital tools and resources from anywhere on the shop floor, facilitating quicker decision-making and more agile production processes. This mobility supports the overall goal of eliminating paper and achieving a fully digital manufacturing environment.

Overcoming Challenges in Adopting Paperless Systems

Adopting paperless systems in manufacturing comes with its own set of challenges that require careful management and strategic planning. Common challenges include cultural resistance, data security concerns, and maintaining data accuracy. To address these challenges effectively, manufacturers must develop robust support systems and provide comprehensive training and resources for their workforce.

The three main strategies to overcome these challenges are change management, ensuring data security, and maintaining data accuracy.

Change Management Strategies

Workforce preparation is crucial to ensure the successful implementation of a paperless environment. Providing interactive training and support from on-site digital coaches can help workers with varying digital skills adapt to new systems. Training on new software and digital tools should emphasize user-friendly features to enhance usability for all employees.

Informing all affected parties, including managers, QA, and line workers, about the transition to paperless manufacturing is essential. Fostering a paperless culture involves training employees to adapt to digital tools, which enhances engagement and productivity.

Addressing cultural resistance and providing adequate support ensures a smoother transition to a paperless environment.

Ensuring Data Security

Data security is a critical concern in paperless manufacturing systems, as digital data must be stored securely and remain accessible. Manufacturers should focus on:

-

Implementing automated data validation checks

-

Enforcing strict access controls to enhance data security

-

Considering industry compliance expectations

-

Evaluating data integrity capabilities when choosing a paperless manufacturing provider

A comprehensive digital audit trail facilitates better management of documents. It also improves the searching and retrieval process for audits. This capability ensures that manufacturers can review documents from specific lines and dates with ease, enhancing traceability and accountability within the production process. Additionally, maintaining a clear paper trail supports these efforts.

Maintaining Data Accuracy

Maintaining data accuracy is vital in digital systems to avoid costly mistakes and ensure reliable operations. The digitization of manufacturing processes helps eliminate human errors from data categorization, ensuring that the data generated is accurate and reliable. Using machine-level data capture further eliminates errors associated with logging data manually, enhancing data quality.

Digital data remains susceptible to human error. This often occurs when it is not managed correctly. The principle of ‘garbage in, garbage out’ (GIGO) signifies that a system’s output is only as good as the input data. Ensuring data accuracy involves implementing rigorous data validation checks and continuous monitoring to maintain high-quality data and support effective decision-making.

Continuous Improvement and Monitoring

Continuous improvement is essential for maximizing the benefits of a paperless manufacturing system. Key actions include:

-

Regularly reviewing and updating processes to ensure they remain efficient and effective

-

Adapting to changes and improving overall operational efficiency

-

Leveraging advanced analytics to gain valuable insights into production performance

-

Using these insights to make informed decisions on optimizations

Additionally, encouraging a paperless culture within the organization supports the overall transition and helps employees embrace the new systems effectively to eliminate paper.

Regularly Review and Update Processes

Regular evaluations of digital processes are essential to ensure they remain efficient and effective. Key aspects include:

-

Conducting regular audits to identify inefficiencies and areas needing adjustment, leading to significant enhancements in workflow and productivity.

-

Using automation in paperless manufacturing to speed up the approval process for regulatory compliance documentation.

-

Ensuring that all processes are up to date and adhere to the required standards.

Periodic reviews of the paperless manufacturing system's performance against established KPIs help ensure the system meets company goals.

-

Conducting regular audits to identify inefficiencies and areas needing adjustment, leading to significant enhancements in workflow and productivity.

-

Using automation in paperless manufacturing to speed up the approval process for regulatory compliance documentation.

-

Ensuring that all processes are up to date and adhere to the required standards.

Making adjustments based on these reviews can lead to continuous improvement initiatives that enhance the overall performance of the manufacturing processes. Staying proactive and regularly updating processes maintains high levels of efficiency and quality control, ultimately improving customer satisfaction, operational excellence, and adhering to quality standards.

Leveraging Advanced Analytics

Advanced analytics play a crucial role in paperless manufacturing by providing real-time data insights that inform strategic decisions and optimizations. These analytics can reveal trends in production performance, uncover hidden inefficiencies, and provide a clearer understanding of production trends. By leveraging machine learning algorithms and reporting filters, manufacturers can achieve better decision-making, operational excellence, and predictive maintenance.

Paperless Culture

Promoting awareness of the benefits of going paperless will help employees adopt new ways of working more easily. Creating a paperless culture is key to getting digital into manufacturing environments. Training sessions and workshops will increase employee understanding of paperless initiatives and make them more comfortable with the change and more likely to adopt the new systems. Key areas to focus on:

-

Promoting awareness of going paperless

-

Creating a paperless culture to get digital into manufacturing

-

Training sessions and workshops to increase understanding and comfort with the change

Having a paperless culture means more efficiency and streamlined workflows in manufacturing. By highlighting the benefits of paperless manufacturing such as reduced paper and improved traceability manufacturers can build a foundation for continuous improvement and digital transformation.

Measuring Success in Your Paperless Journey

Measuring the success of your paperless manufacturing journey is key to making sure your digital transformation is delivering real value. By setting clear key performance indicators (KPIs) manufacturers can track productivity, efficiency and quality control throughout their production processes. Real-time data from your paperless manufacturing system allows you to monitor metrics such as cycle times, defect rates and on-time delivery and see operational effectiveness.

Digital solutions also reduce human error as automated data collection and digital workflows minimises the risks of manual entry. Inventory management is improved as up to date information on raw materials and finished goods helps optimise stock levels and reduce waste. Quality control is improved through continuous monitoring and instant access to production records so you can respond faster to any issues.

By reviewing these metrics regularly manufacturers can see the return on investment (ROI) of their paperless manufacturing initiatives and make adjustments to optimise their processes. Measuring success with real-time analytics enables manufacturers to drive continuous improvement and operational excellence.

Best Practices for Paperless Manufacturing

Going paperless requires a strategic approach and following industry best practices. Start by understanding your current processes and identifying where digital can have the biggest impact. Choose the right paperless manufacturing software – look for user friendly, scalable and integratable with your existing manufacturing software and systems.Full training is key to a successful implementation. Make sure all employees get hands-on training and ongoing support to build confidence in the new paperless manufacturing system. Prioritise data quality by setting up protocols for data entry and validation and ensure your digital data is accurate and up to date.

Data security should be top of mind. Protect sensitive information by implementing robust access controls and encryption. By following these best practices manufacturers can minimise risks, maximise the benefits of paperless manufacturing and set themselves up for a smooth and successful digital transformation.

Common Mistakes to Avoid

Transitioning to a paperless manufacturing system has many benefits but there are common mistakes to watch out for. One big mistake is not providing enough training and support to employees which can lead to resistance, confusion and decreased productivity. Another is not integrating digital solutions with existing systems which can create data silos and fragmented workflows that undermine the benefits of digital transformation.

Not prioritising data quality and security is another big mistake. Poor or unmanaged digital data can compromise decision making and expose the organisation to risk. Implementing paperless manufacturing solutions in isolation without aligning them to the overall digital transformation strategy can limit their effectiveness and create inconsistencies across the organisation.

To avoid these pitfalls manufacturers should invest in full training, ensure seamless integration of digital solutions, maintain high standards for data quality and align paperless initiatives with business objectives.

The Future of Paperless Manufacturing

The future of paperless manufacturing is bright as digital transformation across the manufacturing industry accelerates. As technologies like artificial intelligence, machine learning and the Internet of Things (IoT) evolve manufacturers will have even more powerful digital solutions. The widespread adoption of mobile devices, cloud based platforms and advanced analytics will allow manufacturers to capture and analyse real-time data from every stage of the production process.

Paperless manufacturing systems will integrate with enterprise resource planning (ERP) and product lifecycle management (PLM) tools more and more, providing a single view of operations and quality control. These innovations will enable manufacturers to make faster, data driven decisions, optimise processes and respond to market demand.

As the manufacturing industry continues to go digital paperless manufacturing will be at the heart of manufacturers achieving higher levels of productivity, efficiency and quality.

Summary

In summary, going paperless has many benefits – cost savings, efficiency, quality control, better decision making. By following the steps to go paperless – assessing current processes, choosing the right software and digitising existing documents – manufacturers can make a seamless transition to a digital world. Overcoming challenges through change management, data security and data accuracy will support this transition.

Continuous improvement and monitoring is key to sustaining the benefits of a paperless manufacturing system. Digital quality inspections are crucial in maintaining product standards and traceability in a paperless world. Regularly reviewing and updating processes, using advanced analytics and encouraging a paperless culture will drive operational excellence. Going paperless is not just about eliminating paper it’s about creating a more agile, efficient and competitive manufacturing business. The future of manufacturing is digital – are you ready to take the leap?

More Information

If you want to learn more about paperless manufacturing there are many resources available to support you. Industry associations such as the National Association of Manufacturers have guidance, best practices and updates on the latest paperless manufacturing systems. Online forums and communities like the Paperless Manufacturing Forum allow you to connect with peers, share experiences and get advice on overcoming challenges.

Research reports and whitepapers from leading consulting firms and industry analysts provide in depth analysis of digital solutions and their impact on the manufacturing industry. Case studies and success stories from companies that have gone paperless will give you practical examples and inspiration.

By using these resources you can stay informed, make better decisions and get lasting value from your paperless manufacturing initiatives.

Frequently Asked Questions

What is paperless manufacturing?

Paperless manufacturing is a process that maximizes efficiency by substituting paper documents with digital tools, thereby minimizing errors and streamlining production operations. This shift not only boosts productivity but also promotes a more sustainable approach to manufacturing.

What are the key benefits of going paperless in manufacturing?

Going paperless in manufacturing leads to significant cost savings and improved efficiency, which enhances quality control and decision-making while increasing traceability. Embracing this transition ultimately results in streamlined operations and heightened productivity.

How do I start implementing paperless manufacturing in my organization?

To start implementing paperless manufacturing in your organization, assess your current processes to identify areas for digital upgrades, select appropriate software, and begin digitizing existing documents. A well-planned and executed strategy is essential for a smooth transition.

What challenges might I face when adopting paperless systems, and how can I overcome them?

Adopting paperless systems can present challenges like cultural resistance, data security issues, and maintaining data accuracy. To overcome these, prioritize effective change management, implement strong data security measures, and ensure thorough data validation processes.

How can continuous improvement and monitoring benefit my paperless manufacturing system?

Continuous improvement and monitoring are essential for maximizing the efficiency of your paperless manufacturing system by allowing you to regularly optimize processes and quickly adapt to changes. This proactive approach ensures sustained operational excellence and enhances overall productivity.

Share this

You May Also Like

These Related Stories

Cloud Computing in Manufacturing

Scaling Production Processes for Small Business Manufacturers

No Comments Yet

Let us know what you think