Essential Inspection in Industry: Best Practices for Quality Assurance

Inspection in industry ensures product quality and adherence to safety standards. These inspections evaluate materials and processes at different production stages.

This article explains their role, the types of inspections, and why they are critical for compliance and quality control.

Key Takeaways

-

Inspections are crucial for quality control, identifying potential hazards, and ensuring products meet safety standards, thereby enhancing consumer trust and brand reputation.

-

There are three main types of inspections—pre-production, in-process, and final inspections—each targeting different stages of the manufacturing process to mitigate quality issues effectively.

-

The future of industrial inspections will focus on automation and AI-driven technologies, aiming for increased efficiency, accuracy, and proactive maintenance to improve overall quality control systems.

The Role of Inspection in Industry

Inspections serve as a cornerstone for quality control, ensuring adherence to established standards and regulations. For any manufacturing entity, regular inspections are not just a formality but a critical practice that underpins the entire quality control system. They help in identifying potential hazards, ensuring the functionality of safety equipment, and maintaining workplace safety. Moreover, inspections are instrumental in preventing quality problems by making sure that products meet the required standards before they reach the consumer.

The role of inspections extends beyond just identifying defects; they are vital for achieving manufacturing excellence. Regular inspections can save manufacturers significant amounts of money by preventing costly breakdowns and extending the lifespan of industrial equipment. They contribute to consumer satisfaction by monitoring product quality throughout the manufacturing process, thus fostering trust and loyalty among customers. Buyers and suppliers alike rely on factory inspections to verify adherence to quality standards, thereby enhancing overall product reliability and safety.

A thorough understanding of inspection processes helps manufacturers and buyers improve overall quality and trust. In the following subsections, we will delve deeper into the importance of quality control systems, the various types of industrial inspections, and the significance of regulatory compliance and standards.

Importance of Quality Control Systems

Quality control systems are the backbone of any successful manufacturing operation. They act as gatekeepers, deciding whether products meet the established quality benchmarks before they reach the consumer. The implementation of robust quality control processes helps identify and prevent issues such as defective products and shortcuts in manufacturing, which can otherwise lead to significant quality issues and customer dissatisfaction.

Regardless of the size of a company, implementing quality control systems ensures product quality and consistency. Quality control technicians play a crucial role in this process by identifying unsafe or defective products and rectifying the underlying causes. This proactive approach not only helps in maintaining high-quality standards but also significantly lowers costs associated with rework and product recalls.

Maintaining high-quality standards directly influences brand reputation, enhancing customer satisfaction and loyalty. Delivering consistent product quality is essential to maintain brand reputation and customer trust. Regular industrial inspections reduce the risk of substandard products and support continuous improvement, aligning with government regulatory agencies or industry associations. Quality inspections contribute to a brand’s reputation by helping deliver high-quality products, fostering customer loyalty and trust, and ensuring the product’s quality.

Types of Industrial Inspections

There are three main types of industrial inspections: pre-production inspection, in-process inspection, and final inspection. Each type serves a unique purpose and may vary depending on the different stages of the manufacturing process.

Pre-production inspections focus on verifying the quality of raw materials before they enter the manufacturing phase. This step is crucial for assessing inputs to lower the risk of quality issues later in the production process.

In-process inspections monitor product quality during production, allowing for early detection of defects. These inspections are vital for identifying and rectifying issues before they escalate, ensuring that the production process stays on track.

Finally, final inspections ensure that products comply with required safety and quality standards before distribution. This last step is essential for maintaining customer satisfaction and preventing returns.

Regulatory Compliance and Standards

Factory inspections play a vital role in adherence to regulations, thus minimizing the risk of legal repercussions. Assessing compliance with regulations and standards during factory inspections mitigates risks, thus mitigating risks of penalties and product recalls. Compliance with inspection standards helps companies ensure compliance, avoid fines, and enhances their market credibility.

Quality inspections demonstrate a company’s commitment to industry standards, reducing fines and legal risks. Through regular factory inspections, companies ensure ongoing compliance with industry standards, safeguarding product safety. This proactive approach helps mitigate risks of penalties, legal consequences, product recalls, and reputational damage.

Key Stages of the Inspection Process

The inspection process involves evaluating products and processes at various stages to ensure quality control. It begins with an opening meeting where inspection objectives, scope, methods, and document requests are discussed. This sets the stage for a thorough and focused inspection. Inspectors then undergo the actual inspection process, preparing a detailed report documenting findings post-inspection. During a factory inspection, inspectors will conduct a facility tour to observe the operations, equipment, processes, and working conditions of the factory.

The completed inspection report includes violations, recommendations, and required corrective actions to address identified issues. Quality inspections can be performed at incoming, production, and pre-shipment levels using structured tools. Tools like the Qualityze Inspection Management tool simplify the process and can utilize an AQL table or preconfigured sample size for inspections. Inspection management software can also utilize online customizable checklists for standardizing quality concerns, further streamlining the process.

Let’s explore the key stages of the inspection process: pre-production inspection, in-process inspection, and final inspection.

Pre-Production Inspection

Pre-production inspections are critical for assessing inputs before manufacturing to lower the risk of quality issues. This stage includes checking expiration dates of chemicals and strength testing to determine the quality and quantity of components and raw materials.

It is crucial when suppliers may cut costs as it minimizes communication issues regarding production timelines and quality expectations. Ensuring the quality of raw materials helps a manufacturing company prevent defects and quality issues during production.

In-Process Inspection

In-process inspection refers to monitoring the production process to identify errors early and prevent defective products from progressing further.

Checks performed during in-process inspection include:

-

Physical measurements

-

Visual checks

-

Color checks

-

Weight checks

-

Temperature checks

-

Viscosity checks

When inspections uncover problems, defective products and faulty products should be reworked or the issues addressed in remaining batches. This proactive approach ensures adherence to quality standards and improves production efficiency by resolving issues early.

Final Inspection

Final inspections are crucial in the manufacturing process to ensure that products meet quality standards before shipment. The purpose of final inspections is to verify that the finished product meets all specification quality requirements, including dimensions, performance, and compliance with specifications.

Ensuring products pass final inspections is essential for maintaining customer satisfaction and preventing returns.

Advanced Techniques in Industrial Inspection

Innovations like AI, machine learning, and IoT are transforming inspection management by enabling automated, real-time data-driven processes. Technological advancements like AI integration are leading to more automated inspection processes. Automated inspection systems utilize machine vision, AI, and deep learning for enhanced accuracy.

Inspection robots equipped with advanced sensors, cameras, and tools such as thermal and gas detection are becoming commonplace. Automating inspection tasks can significantly reduce time and resources while improving reliability and reproducibility.

Let’s delve deeper into automated inspection systems, remote and virtual inspections, and AI and data analytics in inspection.

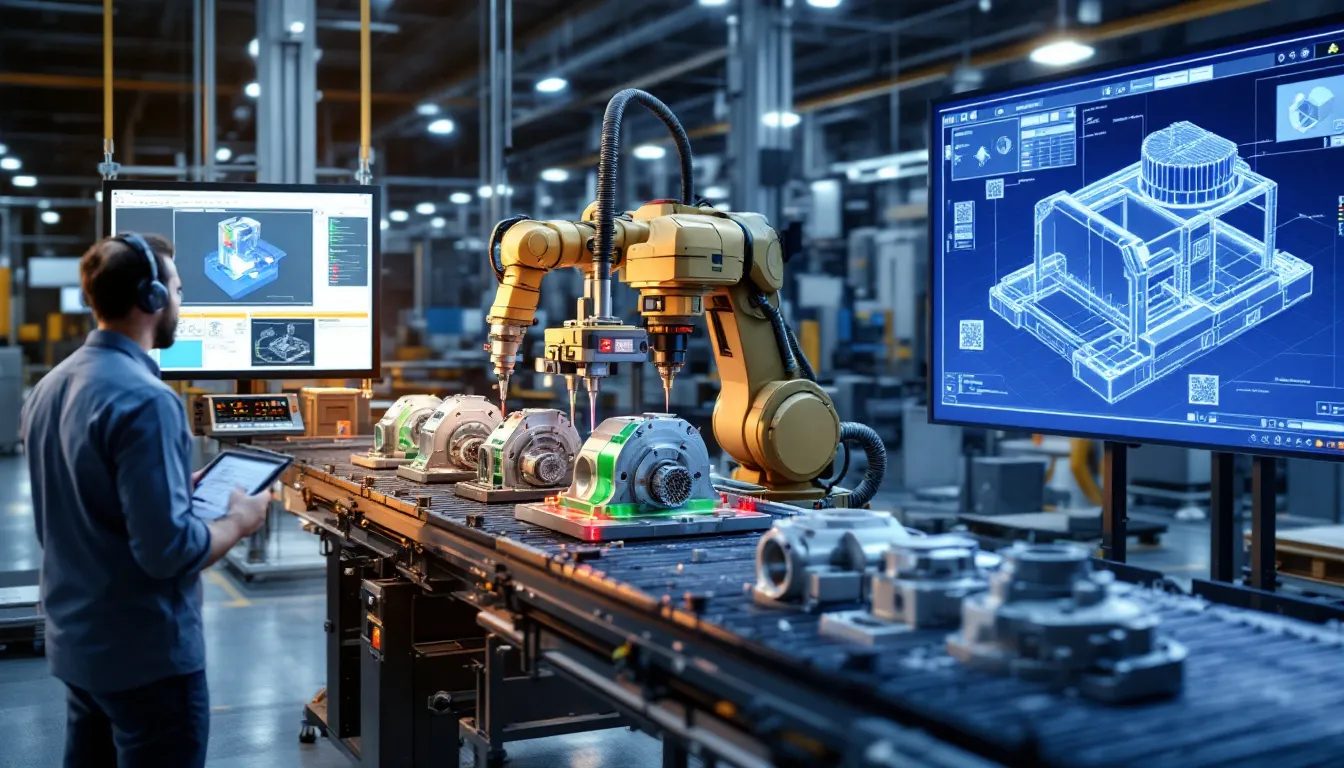

Automated Inspection Systems

Coordinate measuring machines enable precise measurement and defect detection in production. Integrating various inspection technologies can enhance the detection of diverse contaminants in manufacturing. Automated inspection systems are crucial for enhancing quality control and ensuring product specifications in industrial settings.

The adoption of automated systems in inspections leads to improved efficiency and accuracy in identifying product defects.

Remote and Virtual Inspections

The technologies used in remote inspections include video conferencing, augmented reality, and remote collaboration tools. Conducting remote inspections reduces travel costs, lowers carbon footprints, and enables timely inspections. Emerging remote inspection technologies include augmented reality features for enhanced visualization.

Ongoing training on new regulatory requirements and emerging inspection technologies is necessary to keep inspectors knowledgeable.

AI and Data Analytics in Inspection

Data-driven quality intelligence for inspections utilizes IIoT sensors, advanced analytics, and machine learning algorithms. Predictive analytics in inspections help identify potential quality failures before they occur. Predictive maintenance utilizes historical data analysis to forecast equipment failures, minimizing downtime and repair costs. Additionally, data gathered during inspections helps to develop a preventive maintenance schedule, ensuring equipment reliability and operational efficiency.

Artificial intelligence and data analytics significantly enhance inspection processes by enabling proactive decision-making and failure predictions.

Implementing Effective Inspection Processes

The inspection process involves several essential steps including defining quality standards, sampling, inspection methods, reporting, and implementing corrective actions. Careful planning and execution are essential for implementing an effective quality inspection program. Additionally, there must be a commitment to continuous improvement. Modern quality inspections integrate automation to enhance reliability and customer satisfaction. Statistical sampling techniques are commonly used in quality inspection to balance inspection costs and product quality.

Let’s break down the practical steps for developing an inspection plan, training and certification for inspectors, and continuous improvement and audits.

Developing an Inspection Plan

Clear scope and objectives of the inspection should be defined to ensure targeted outcomes. Key objectives for inspections include identifying risks, improving product quality, and ensuring compliance with relevant standards. Preparing for a factory inspection involves understanding the inspection requirements and defining the scope and objectives, which are critical for a successful and efficient inspection process.

Creating a checklist tailored to specific inspection needs can enhance efficiency and consistency in procedures. Factors such as product complexity, risk profiles, and past quality data must be assessed when developing an inspection plan.

Training and Certification for Inspectors

Skilled inspectors can accurately identify defects and make informed decisions. The aging workforce leads to a shortage of skilled inspectors and creates an experience gap between experienced and less-experienced inspectors. Training programs should be updated regularly to include the latest quality standards and inspection technologies.

Virtual inspections allow experienced inspectors to guide and mentor personnel across multiple locations.

Continuous Improvement and Audits

Regular audits of inspection processes help identify areas for improvement and ensure ongoing compliance with quality standards. Internal audits are conducted prior to inspections to identify areas of non-compliance and address them.

During the closing meeting after an inspection, inspectors provide feedback, discuss areas for improvement or non-compliance, and may suggest corrective actions. The inspectors will hold a closing meeting with the factory authority after the inspection to provide feedback on their findings and discuss areas for improvement, ensuring transparency and actionable outcomes.

Addressing Common Challenges in Industrial Inspections

Regular inspections help identify potential hazards, contributing to a safer workplace and preventing accidents. An effective industrial inspection identifies hazards and allows for corrective measures. The consequences of poorly manufactured industrial equipment include parts scrapping, recalls, and a tarnished company image. Compromising on quality can drive customers away, risk lawsuits, and lead to bad press. Defective products create monetary, physical, and emotional costs for companies.

Manual inspections are associated with greater risks of human error, increased likelihood of accidents, and overlooked issues. Compromising safety and quality in inspections can lead to severe fines and damage to the company’s reputation. Rising costs associated with compliance can stem from factors like manual inspection risks and potential risks and potential fines.

Inspection robots contribute to data consistency by performing repetitive tasks with greater precision and shorter intervals. Let’s explore how to mitigate human error, handle large volumes of inspection data, and ensure proper documentation and record-keeping.

Mitigating Human Error

Common causes of mistakes in manual inspections include various factors such as repetitive tasks, fatigue, lack of concentration, and human error.

The perception of manual inspection as repetitive and labor-intensive affects the younger workforce’s interest in this area. Subjective decision-making in manual inspections can lead to inconsistencies in inspection results. Missed defects in manual inspections can result in product failures, accidents, and environmental damage.

Using robotic inspection systems reduces the risk of human error in inspections. Drones can access hard-to-reach areas during inspections, minimizing human risk and offering cost savings. Leveraging advanced technologies allows companies to mitigate potential hazards, ensure safety, and uphold high-quality standards.

Handling Large Volumes of Inspection Data

Organizations can identify improvement opportunities in quality inspection by leveraging insights from audits, inspection data, customer feedback, and quality metrics. The sheer volume of inspection data generated during industrial inspections can be overwhelming. However, by efficiently analyzing vast amounts of data, companies can implement targeted corrective and preventive actions.

High-resolution images and detailed inspection reports provide valuable insights that help in making informed decisions and improving overall quality. Advanced data analytics tools facilitate the processing and interpretation of large datasets to analyze vast amounts of data, enabling companies to identify trends, predict issues, and optimize inspection processes.

Ensuring Proper Documentation and Record-Keeping

Accurate documentation demonstrates a commitment to compliance and continuous improvement. Ensuring that documentation is up-to-date before a factory inspection is crucial for compliance and quality control facilitation. Types of documentation to be gathered include production procedures, quality control records, supplier agreements, and certifications.

Permits, licenses, safety records, training records, and maintenance logs must be accessible for thorough documentation review during inspections. Inspectors primarily review documentation. Their main goal is to assess compliance with regulations. Routine audits of inspection processes and documentation are essential for ensuring system effectiveness and compliance.

Industrial inspections produce a record of quality control efforts that helps in tracking compliance and identifying areas for improvement.

The Future of Industrial Inspections

Future industrial inspections will increasingly utilize:

-

Autonomous robots and drones that can access hard-to-reach areas

-

Upcoming remote inspection technologies, anticipated to include real-time data overlays and virtual walkthroughs

-

Seamless integration with quality management systems

-

AI-powered visual inspection systems that will detect defects by analyzing high-resolution images or video footage, enhancing accuracy. Autonomous robots and drones are disrupting the field of automated inspection significantly, offering new possibilities for efficiency and precision.

The use of automated and data-driven technologies in quality inspection will improve efficiency, accuracy, and decision-making capabilities.

Let’s explore the future trends: mobile and autonomous inspection technologies, integration of IoT and smart sensors, and predictive maintenance and proactive approaches.

Mobile and Autonomous Inspection Technologies

Drones with high-resolution cameras and strong flight capabilities are particularly suitable for inspecting hard-to-reach areas. Mobile robots and drones have become essential tools in industrial inspections, especially for accessing hard-to-reach areas safely and efficiently.

These technologies not only improve safety but also enhance the thoroughness and efficiency of inspections.

Integration of IoT and Smart Sensors

Smart sensors paired with IoT can facilitate immediate insights and improve quality control systems. An end-to-end solution for data analysis in inspections provides quick and efficient fault detection.

While stationary IoT sensors have limitations in industrial inspections and cannot replace manual inspection entirely, their integration with smart sensors offers a significant boost to the overall inspection process.

Predictive Maintenance and Proactive Approaches

Predictive maintenance involves using data analytics to assess the condition of equipment and predict potential failures before they occur. AI and data analytics enhance predictive maintenance processes by analyzing historical data to identify patterns that indicate equipment health and potential failures.

Integration of IoT and smart sensors allows for real-time monitoring and data collection, which is essential for effective predictive maintenance strategies. By implementing predictive maintenance, industries can reduce downtime and maintenance costs while improving operational efficiency and equipment reliability.

Summary

Mastering the inspection process in industry is crucial for maintaining high standards of quality, ensuring regulatory compliance, and enhancing customer satisfaction. From pre-production to final inspections, each stage plays a vital role in identifying defects, preventing quality issues, and ensuring that products meet the required standards. Advanced techniques such as automated inspection systems, remote inspections, and AI and data analytics are revolutionizing the inspection landscape, making processes more efficient and accurate.

Looking ahead, the integration of mobile and autonomous inspection technologies, IoT and smart sensors, and predictive maintenance strategies will continue to drive improvements in industrial inspections. By staying ahead of these trends and implementing effective inspection processes, companies can ensure consistent product quality, reduce costs, and maintain a competitive edge in the market.

Frequently Asked Questions

What are the main types of industrial inspections?

The main types of industrial inspections include pre-production inspection, in-process inspection, and final inspection, each serving a distinct role at various phases of the manufacturing process. Understanding these inspection types is essential for ensuring product quality and compliance.

How do quality control systems benefit a manufacturing company?

Quality control systems significantly benefit a manufacturing company by ensuring products meet quality standards, thereby preventing defects and minimizing costs associated with rework and recalls. This ultimately enhances brand reputation and boosts customer satisfaction.

What technologies are used in remote and virtual inspections?

Remote and virtual inspections utilize video conferencing, augmented reality, and remote collaboration tools. These technologies facilitate timely inspections while minimizing travel costs.

How can companies mitigate human error in inspections?

To effectively mitigate human error in inspections, companies should implement robotic inspection systems and advanced technologies like drones, which enhance accuracy, improve safety, and ensure consistent quality standards.

What is predictive maintenance, and how does it benefit industrial inspections?

Predictive maintenance utilizes data analytics to foresee possible equipment failures, significantly reducing downtime and maintenance costs. This approach enhances operational efficiency and boosts equipment reliability, benefiting industrial inspections immensely.

Share this

You May Also Like

These Related Stories

Top AI Use Cases in Manufacturing: Enhancing Efficiency and Innovation

Industrial-Grade AI: Transforming Operational Efficiency

No Comments Yet

Let us know what you think